Industry 5.0 is redefining market dynamics, the competitive landscape, and most importantly the science of performance metrics. Purpose-driven innovation across industries is one of the major driving aspects of the latest industrial revolution. The idea is to enhance what we have established with Industry 4.0.

The only way to build on what we have is by knowing what we have and extracting, evaluating, visualizing, and interpreting what we have at hand. For all industries, this is the most fundamental aspect for stepping up from 4.0 to 5.0 and then maintaining that competitive edge. And hence artificial intelligence (AI) has been one of the major backbones of this transition.

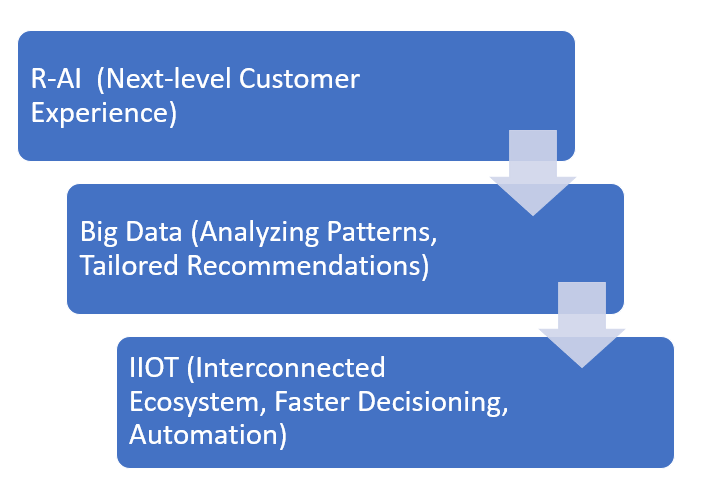

While AI continues to be crucial to reshaping industries, regenerative AI (R-AI) enables optimizing and empowering industry processes with data at the center stage. The usage of R-AI leads to better and accurate decision making, automation and next level customer experience. It’s important to note that R-AI works together with big data and Internet of Things (IOT).

Using IOT or Industrial Internet of Things (IIOT) helps a manufacturing organization be above the cut. Ensuring you have better visibility on your manufacturing ecosystem can be achieved by first making sure all elements of the ecosystem not only work in an interconnected way but also can capture what they do, which may help optimize the ecosystem further or be proactive than reactive. Interconnected network can be achieved by harnessing the capabilities of IOT by having the right placement of sensors to collect and store real time data, and this data when analyzed regularly can help someone at control center to have a double click details for making faster decisions, have a proper alert and awareness mechanism and ability to handle what-if situations through automated and intelligent decision capabilities.

R-AI strengthens your commitment to customers by regularly analyzing patterns of customer specific data and make tailor made recommendations helping overcome any supply chain disruption factors and market fluctuations and hence reducing risk factor thus enabling cost savings.

Lastly, having R-AI also helps improve operational efficiencies and reduces the risk of obsoleting a working model, this is because the continuous analysis of data from the ecosystem will help you have a more agile way of working and optimizing your current resources thus making the footprint more scalable.

Hence, R-AI is becoming crucial to the manufacturing landscape driving organizations to be sustainable, cost effective and most importantly lead the way to transformation.