“The journey of a thousand miles begins with a single step, but the direction of that step is crucial.”

As we begin the next power-packed and AI-ambitious quadrans-centennial, the manufacturers seek a paradigm shift in their production outcomes with exponential increase in OEE & other KPIs. The urge to own an AI-influenced Smart factory has been the driving force. While only ~5% of the enterprises have scaled their way out to realize a intelligent and digitized factory, an expeditious revolution awaits to transform the masses to create a tech-democratized industrial society.

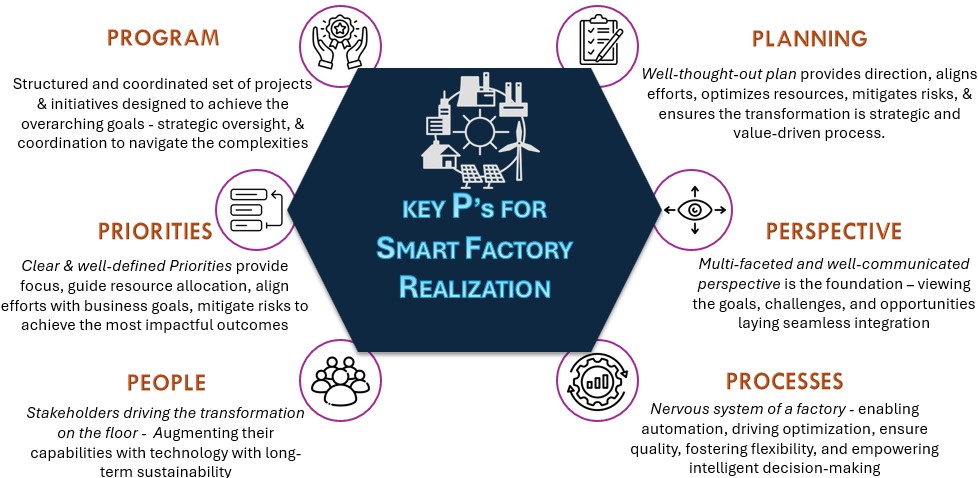

6P’s for Smart Factory Realization

Start it RIGHT

As morning shows the day, it is imperative that achievable targets are set, roles are onboarded, and the velocity is defined. To get it going, the enterprises must follow the basic guidelines as follows:

• Create Baseline & Targets – set right and achievable targets, scientific benchmarking of current KPIs and positioning the to-be accordingly.

• Comprehensive Assessments – Process maturity, identifying opportunities, IT-OT integration efficiencies.

• Build for Masses – Key stakeholder identification, build consensus on user stories

• Driven by Prioritization – use case categorization & prioritization, target low-hanging ones

• The first shot matters – Assess site maturity & readiness, Evaluate for systems, resources, organization and appetite

Key SUCCESS Factors

Pivoting the journey with success factors at the core are crush of such transformational initiatives. The factors drive and model the flow of the program; once we are past the great beginning: –

• Seek Optimizations – Schedule & resource optimizations, Identify process loopholes & areas of improvements

• Develop Comprehensive pilot – Complete systems integration covering all apps, ROI to be forecasted and tracked

• Golden templates for scale-outs – Adopt templatized approach: Global Template to maximize fit for all sites, avoid customizations to the template

• Users at the center – Achieve 100% saturation in app usage through user centric adoption management, Early bird enrollment for success

• Force multiplier with Technology – Select technology fitting to processes with futuristic views, Automation is key, Cloud First Approach, AI everywhere

Mitigating the CHALLENGES

Key to success in any initiative is assessing the risk at the outset and plan out the robust mitigations to nail it down. As we roll along the difficult terrains, be ready to wither the key challenges: –

• Address nuances across sites – Process and Technology, Harmonization is the key

• Solution Architecture – Key for global template approach, must be scalable for future enhancements & value-additions

• Automating Legacies – Legacy Machines are the bottlenecks; plan it right

• Leadership Commitment – Stay committed to the fruitful journey of modernization; adapt to the budget and duration

• Path to ROI – Stay focused on the journey to realize the ROI in a sustainable way

Inch by inch, anything’s a cinch – Sailing along with the guiding principles laid above are essential to laying down a tech-oriented Smart Factory. A subtle preparation, detailed planning, meticulous execution with lots of flexibility, razor focus, commitments on the ground and setting a good precedent shall set the tone for such a wonderful voyage. Seeking alternatives, sidelining painful factors, striving for workarounds etc. can be the awful hinderances to plug you off track.