This blog describes how LIMS is interfaced with SAP QM. Using this interface, SAP can create an Inspection LOT automatically and log samples along with required tests.

Based on the quality test results LIMS can send results back to SAP called as usage decision with disposition status of inspection LOT of which testing is completed. This integration can significantly streamline quality control processes, improve data accuracy, and enhance overall operational efficiency.

Terms used

Inspection Lot – ERP creates an inspection lot when material is to be tested, it will have details like material number (product), plant, inspection date, customer, inspection lot type, quantity of material inspected, etc.

Inspection Lot Type – Defines Raw Material / Finished good and mapped to Sampling Point in LIMS.

Inspection Plan – This is mapped with LIMS -Product specifications, it defines the inspection characteristics and specifications that will be used to inspect the material on the inspection lot.

UD / Usage Decision – Inspection lots receive usage decisions indicating: 1.) Status of lot – Open/Closed, and 2.) Disposition of the material on the inspection lot will be (in -spec – USE, Out-of Spec- Reject/Scrap).

Work Centers – denotes physical location of resources/production line.

Specifications – SAP defines specifications by plant, material, inspection type, and inspection characteristic. This corresponds to product, sampling point and component within LIMS. SAP defines several limit levels; e.g., plausibility and tolerance.

Inspection Characteristics or Master Inspection Characteristics – In SAP an inspection characteristic corresponds to a component on an analysis in LIMS. There are two types of inspection characteristics: quantitative (numeric) and qualitative (list).

Lot Associated Samples: Samples associated tests that are required for the disposition of Lot, LIMS will prevent disposition of lot until all samples are reviewed

Sampling Point – The primary sampling point refers to specific combination of sampling point and product grade that has been setup as a quality master data in LIMS.

criteria used to determine how many samples to draw from a quantity of material in a Lot. This corresponds to the Sampling Plan in LIMS.

Background

QM IDI is Inspection Data Interface in Quality Management – is an open interface designed for exchanging inspection processing data between the SAP QM (Quality Management) application component and external systems; by leveraging QM-IDI, LIMS can be integrated to download the inspection lot along with inspection characteristics and push the UD status back to SAP-QM

Once Inspection lots and inspection characteristics is created within SAP. The process begins when an inspection lot is created in SAP. This process will be used to test only Raw Material and Finished good samples and micro, water samples (EM samples) will not be created by SAP Interface as part of Inspection download process.

When an Inspection lot is created in SAP, corresponding LOT or Batch is created in LIMS leading to log samples in a LIMS. This is based on the mapping of inspection characteristics with Product specs and analysis (master data in LIMS). Inspection characteristics will have multiple fields (metadata) but LIMS will use only limited /sub-set of fields.

ERP/SAP V/s LIMS

ERP will serve as the central hub for product recipes, process flows, specifications, and sampling protocols. It will generate the necessary inspection methods, characteristics, and units of measure, which will be linked to corresponding analyses, components, and units in LIMS.

LIMS will then manage the laboratory operations, sample flow, analytical methods, and execution. It is important for both ERP/SAP and LIMS team to work in cohesion and do initial mapping of the material, inspection characteristics, inspection plan with product specs, test method, UoM, sampling plan etc.

How LabWare LIMS and SAP – QM IDI interface works:

LabWare LIMS provides OOB solution for SAP Interface – Module# M0189 (One of the most widely used Module)

To enable this interface , need to have following pre-requisites,

Pre-requisite for SAP

The SAP client needs to be installed on the main LIMS server to download inspection lots from SAP or send results / usage decisions back to SAP.

Privileged account with access to SAP – This account will be used for logging into SAP in order to download inspection lots and send results / usage decisions back to SAP. This account is a standard SAP user account with no password expiry condition. It utilizes existing RFC function modules in SAP to handle the data transfer and processing. Configured modules is to trigger specific actions in LabWare

To ensure seamless integration between SAP and LabWare LIMS, it’s crucial to establish a clear connection between inspection lots in SAP and work centers in LabWare.

Pre-requsite for LIMS

The LabWare LIMS tables especially LOT are updated as per the defined mapping.

LabWare’s SAP interface module must be installed.

Log-in templates for Lots and Samples must be in place before downloading inspection lots from SAP.

Master Data also needs to be setup as per the requisite requirement.

How LabWare LIMS Objects Are Created from SAP Data

There are seven different objects that are created in LIMS from SAP data. Of these seven objects, four of them have a link to corresponding objects in SAP as noted below. The seven objects are created in the following order:

Lists

Lots

Samples

Analyses – has a link to the inspection method using the inspection method identifier.

Components on an analysis – has a link to the inspection characteristic using the inspection characteristic short text description.

Units – has a link to the units of measure in SAP

Product specifications – part of the product specification definition is the product name (material). This is linked to the material number in SAP

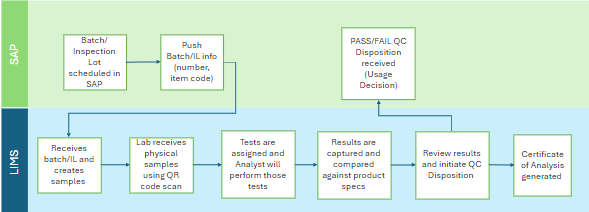

How interface works

In summary :

SAP as the Master System:

Manages product recipes, process flows, specifications, and sampling protocols.

Creates inspection methods, characteristics, and units of measure.

Sends inspection lot information to LIMS.

LIMS as the Execution System:

Receives inspection lot information from SAP.

Creates samples and links them to SAP-defined tests.

Performs laboratory analyses and enters results.

Sends completed test results and valuation back to SAP.

Manages additional non-SAP samples and their associated tests.

Integration Workflow:

SAP creates an inspection lot.

LIMS receives the lot and its inspection characteristics.

LIMS creates the Lot and its associated samples and assigns tests.

LIMS performs tests and enters results.

LIMS sends completed test results and valuation back to SAP.

SAP makes a usage decision based on the results.

Best practices for LIMS / SAP Integration :

Below are some best practices to consider for LIMS -SAP integration

1. Define Clear Integration Goals:

Identify Key Integration Points: Identify the specific areas where data needs to be shared between the two systems (e.g., Inspection Lot, sample information, test results, material characteristics).

Define Data Flow: Define the direction of data flow (LIMS to SAP, SAP to LIMS, or bidirectional) and trigger points for the frequency of data transfer.

2. Choose the Right Integration Method:

File Transfer: A simple but less efficient method, suitable for small-scale data transfers.

API/Web services Integration: A more robust and flexible approach, allowing for real-time data exchange.

Middleware Integration: A complex but powerful solution for complex integrations, often used for large-scale, enterprise-wide integrations.

3. Data Mapping and Standardization:

O/P Data Formats: Ensure that data formats for receiving and sending ends are templatized.

Map Data Fields: Define mappings between data fields in LIMS (e.g prod specs) and SAP (Mat char) to ensure seamless data transfer.

4. Security and Compliance:

Data Security: Implement encryption and data masking to secure the data

Compliance Adherence: Ensure to maintain audits and track changes as per ESER requirement

By following these best practices, you can ensure a successful LIMS and SAP integration that improves efficiency, reduces errors, and enhances decision-making.

Advantages of having LIMS and SAP integrations are

Real-time Data Synchronization in both systems for data accuracy

Overcome manual transcriptional errors reducing Turnaround time for Usage Decision

Increased Efficiency and Productivity by automated workflows

Enhanced compliance by automated data capture and tracking in both systems

Conclusion:

In conclusion, a well-integrated LIMS-SAP systems can revolutionize laboratory operations. By streamlining workflows, improving data accuracy, and enhancing decision-making, organizations can achieve significant operational efficiencies. This interface helps to enhance decision making by posting UD status in SAP.