In the face of increasing global competition and the relentless march of technological advancement, manufacturers are under immense pressure to optimize operations, enhance quality, and accelerate time-to-market. While SAP Digital Manufacturing offers a compelling path for digital transformation, SAP Manufacturing Integration and Intelligence (MII) remains a critical asset for many organizations. MII’s proven track record, robust functionality, and established integrations within existing IT infrastructures make it an indispensable component of their manufacturing operations, not a legacy system to be immediately replaced.

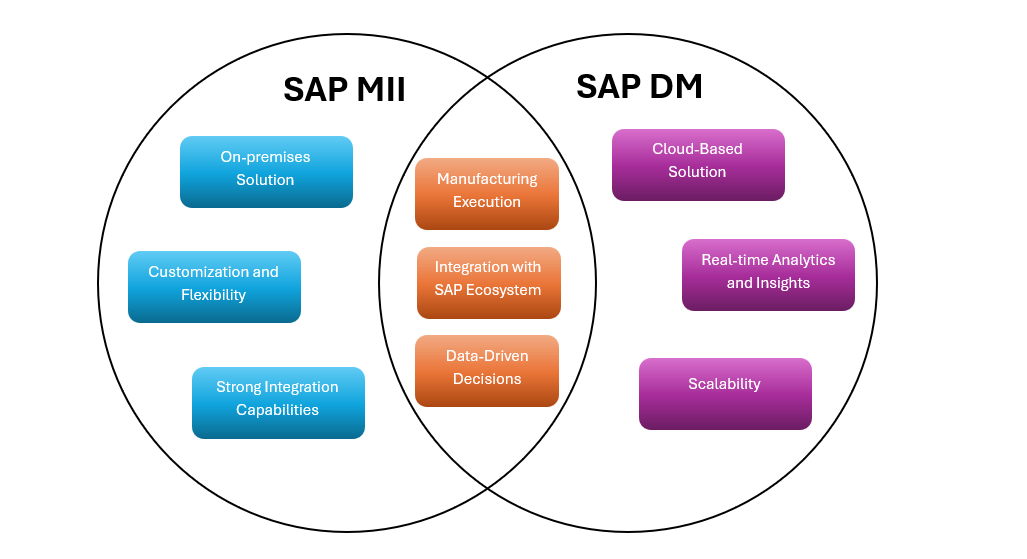

SAP MII and SAP Digital Manufacturing can work together by integrating data, enabling phased transitions, and creating a hybrid solution. This combined approach improves data quality, streamlines operations, and accelerates digital transformation.

SAP Manufacturing Integration and Intelligence (SAP MII) acts as a bridge between production facilities and enterprise systems, providing a real-time overview of manufacturing operations. It empowers businesses to monitor, assess, and benchmark the effectiveness of plants and equipment, even with diverse automation setups.

SAP Digital Manufacturing (SAP DM) is a cloud-based Manufacturing Execution System (MES) that connects production and business operations within the supply chain. It provides a comprehensive, global view of all manufacturing facilities by linking enterprise systems with shop floor equipment. This connection allows for centralized monitoring and management of production activities across all plants, extending down to the work center level.

The Indispensable Synergy

SAP MII: The Bridge to Operational Intelligence

While SAP Digital Manufacturing provides the strategic framework, SAP MII acts as the critical bridge connecting the digital and physical worlds. It excels at:

- Integration Capabilities:

SAP MII serves as a bridge between enterprise-level systems (such as SAP S/4HANA ERP) and shop floor systems (including MES, Historians, and SCADA). It employs various connection methods like JCo, JRAs, and web services for SAP Enterprise Services to facilitate seamless data exchange between these disparate systems.

- Business Logic Services:

SAP MII offers business logic services that allow users to create custom business logic transactions using a graphical editor. These transactions can include data I/O operations, dynamic graphics, flow logic, and XML manipulation

- KPI Framework:

SAP MII offers a framework for defining and managing manufacturing-related Key Performance Indicators (KPIs). This framework enables users to establish a range of KPIs, incorporating calculations, target values, and alert mechanisms that trigger notifications when performance deviates from established thresholds.

- OEE Management:

SAP MII offers OEE (Overall Equipment Effectiveness) management capabilities, a crucial metric in manufacturing. By analyzing OEE in real-time and historically, production managers can assess equipment performance, pinpoint improvement opportunities, and understand how these affect overall manufacturing operations.

- Visualization and Reporting:

SAP MII supports the development of visualization and reporting tools using Business Objects Dashboards and Crystal Reports. Users can create customized, interactive screens and specialized reports to visualize data

SAP Digital Manufacturing

This comprehensive suite empowers manufacturers with a digital thread across the entire product lifecycle. It encompasses:

- Cloud-based:

Cloud-based solutions, often delivered as SaaS (Software as a Service), offer numerous advantages, including reduced IT overhead by eliminating the need to manage on-premise servers, thereby lowering infrastructure costs and maintenance efforts. Additionally, they provide unparalleled scalability and flexibility, allowing users to easily adjust resources based on demand and access the system from any location with an internet connection. Furthermore, cloud deployments typically exhibit significantly faster implementation times compared to traditional on-premise installations.

- Real-time analytics and AI/ML:

Cloud-based solutions empower enhanced decision-making by leveraging real-time data analysis, predictive maintenance, and AI/ML capabilities, leading to improved operational efficiency, proactive issue resolution, and optimized production schedules. This positions businesses for Industry 4.0 readiness, enabling seamless integration of cutting-edge technologies like IoT, robotics, and advanced automation.

- Modern architecture:

Cloud-based solutions enhance the user experience by providing a more modern and user-friendly interface with improved usability and mobile access. Furthermore, they offer enhanced integration capabilities, enabling seamless connectivity with other SAP solutions and third-party systems, facilitating a more holistic view of the entire manufacturing value chain.

- Continuous innovation:

Cloud-based solutions benefit from regular updates and enhancements directly from SAP, ensuring the system remains current with the latest industry trends and technologies. This provides users with access to the most recent features and improvements without the need for manual upgrades or maintenance.

The Combined Power of SAP MII and SAP Digital Manufacturing

- Enhanced Data Integration and Enrichment:

MII can act as a data aggregation hub, collecting data from various shop floor devices and systems. This data can then be integrated with SAP DM, enriching its real-time insights and providing a more comprehensive view of manufacturing processes.

- Phased Transition:

For organizations with significant investments in MII, a phased transition approach can be beneficial. MII can continue to handle specific functions or integrate with certain legacy systems while SAP DM is gradually implemented for newer functionalities or areas of the manufacturing process.

- Hybrid Approach:

A hybrid approach can leverage the strengths of both platforms. MII can be utilized for data acquisition and integration from specific equipment or systems that may not be easily integrated with SAP DM. SAP DM can then leverage this integrated data for advanced analytics, predictive maintenance, and other advanced functionalities.

- Improved Decision Making:

By combining the data collection and integration capabilities of MII with the advanced analytics and real-time insights of SAP DM, manufacturers can gain a deeper understanding of their operations.

Discover how to seamlessly connect MII and DM for enhanced manufacturing efficiency: Integration with SAP MII | SAP Help Portal

Benefits of Integrating SAP DM and MII

- Accelerated Digital Transformation:

MII’s existing integrations and data collection capabilities can significantly speed up the transition to a modern, cloud-based system like SAP DM. This phased approach minimizes disruption to ongoing operations.

- Mitigating Risks in MII to DM:

A phased migration from MII to DM minimizes risk by allowing for gradual implementation, thorough testing in a live environment, and minimized disruption to daily operations. This approach ensures a smoother transition, reduces the impact on business continuity, and maximizes the benefits of the new technology.

- Improved Data Quality and Consistency:

Combining data sources from MII with the data management and quality assurance features of SAP DM enhances data accuracy and consistency across the entire manufacturing ecosystem. This leads to more reliable insights and better decision-making.

- Enhanced Operational Agility:

The integration allows for faster responses to market changes, improved production planning, and quicker time-to-market for new products. Real-time data insights from SAP DM, combined with the flexibility and scalability of the cloud platform, empower manufacturers to be more agile.

- Reduced Total Cost of Ownership (TCO):

A phased approach can optimize costs. By leveraging existing MII investments and gradually migrating functionalities, organizations can minimize disruption to operations and reduce the overall TCO of their digital transformation journey.

- Stronger Foundation for Industry 4.0:

Combining MII’s data integration capabilities with SAP DM’s advanced analytics and AI/ML functionalities provides a robust foundation for implementing Industry 4.0 technologies, such as IoT, robotics, and advanced automation.

Potential Challenges in Integrating SAP MII and SAP DM

While using SAP MII and SAP Digital Manufacturing (DM) together offers significant benefits, there are also some potential cautions to consider:

- Complexity of Integration:

Integrating two separate systems can introduce complexity. Ensuring seamless data flow, maintaining data consistency, and troubleshooting integration issues can require careful planning and ongoing maintenance.

- Potential for Data Redundancy:

If not carefully managed, data redundancy can occur, leading to inconsistencies and increased data management overhead.

- Skill Requirements:

Managing and maintaining a hybrid environment requires a skilled workforce with expertise in both SAP MII and SAP DM.

- Maintenance Overhead:

Maintaining two separate systems can increase maintenance overhead compared to a single, integrated solution.

- Potential for Vendor Lock-in:

Relying heavily on two SAP products can potentially increase vendor lock-in, limiting flexibility and potentially increasing long-term costs.

Conclusion:

At present, Combining SAP MII and SAP Digital Manufacturing offers immediate advantages by creating a more holistic and integrated view of manufacturing operations. This deeper insight facilitates real-time, data-driven decision-making, boosts operational efficiency, and increases responsiveness to market fluctuations. Furthermore, this integration can streamline workflows, minimize manual data entry, and enhance overall productivity. By capitalizing on the synergistic capabilities of SAP MII and SAP Digital Manufacturing, businesses can strengthen their competitive position and foster ongoing improvements in manufacturing.