As with Covid19, there were shutdowns in various countries leading to closure of factories and manufacturing units. There was also a restriction on the movement of material between different locations irrespective of the mode of transport. And, with the loss of human lives across the globe created somewhat of a labor or skillset shortage. This has led to major supply chain disruptions in many industries and even with the recovery initiatives in place, the optimum levels are still very far. With all these imperfections, there is a need to quantify and gauge the problem. To do that we first need to identify the economic drivers and then create, test, and refine prediction models. The concept of looking at data over a period to determine the forecast and availability needs have gone for a toss. There would not only be the factors that was driving demand is important but also the external factors that can change the economic, geographical, and political scenarios. All these need to come into the prediction models and refinement of them based of the various factors would be of utmost importance.

Now the question is what are the challenges that have arose from this or may arose from similar scenarios as this.

a. Cost Changes or Increases – With the increase in commodity prices and raw material prices because of supply chain challenges due to reduced manufacturing, shutdowns in various factories across the world creating a major shortage of raw material or commodity prices. This has resulted in idle times for various factories impacting the overall expenses for the factory or organization.

Now to reduce such additional costs different organizations look at various measures. Stringent pricing agreements with raw material suppliers and contract manufacturing are needed to limit price variations. Use of prediction models to forecast likely future demand for essential commodities and build in the ordering cycle. External factors like tariff s, global demand, over supply, economic change or geopolitical uncertainty bring in risk with contingency plan.

b. Sourcing Delays & Routing through Supply Chain – It is important to understand bottlenecks and order shortages with manufacturing parts and take into consideration machine learning for determining likely future demand and IOT devices to track materials & parts for route optimization & production scheduling

c. Speed to Market impacting Consumer Expectations and Competitiveness: This impact sales as with technology expectations change very fast and with newer products coming in day in and out, time to market has become a very essential component of the success of a product. To do so, early insights into R&D coupled with engagement with stakeholders as suppliers, manufacturers or marketing team is very essential. Risk identification and management to reduce delay risks or quality impacts are also important in this process.

d. Inefficient Transportation leading to Stock level mismatch and distribution network issues: AI and machine learning has become an important entity in this process to utilize multiple modes of transport and optimize routings. There is a need for working with a large entity of logistics providers to attain to the changing distribution needs.

e. Technology and IP Theft: There need to be a complete risk assessment of the supply chain with regular audits at various stages in the supply chain processes including suppliers and manufacturers.

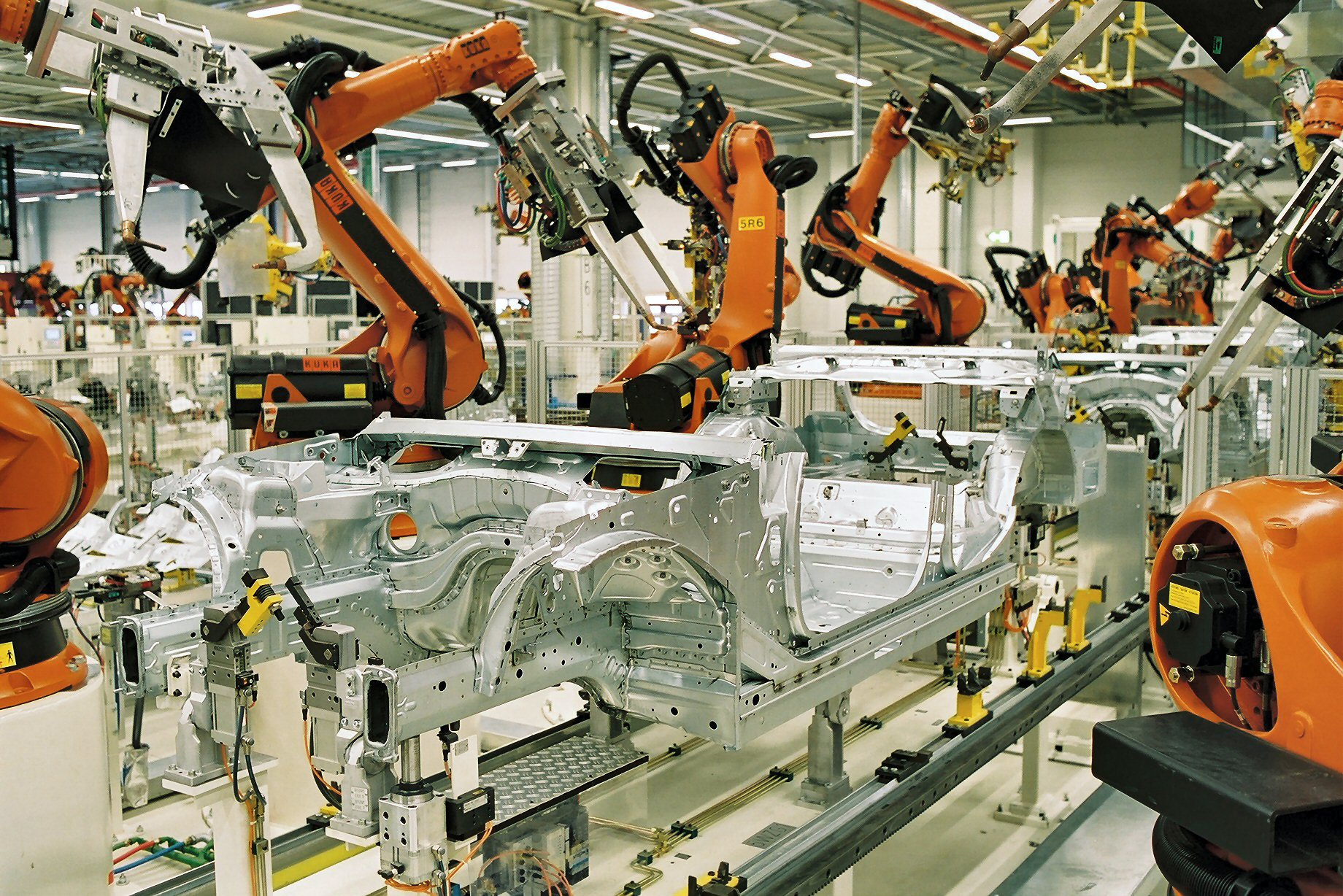

f. Workforce Management: With the pandemic impacting human lives, there has been a major shortage of skilled workforce resulting in quality risks and manufacturing turn-around times. And this has triggered larger organizations to work with small boutique organizations for a specific or special skilled work. This also has triggered a major workforce management in terms of wages increments and training of skill force to address and reduce the impact thus increasing the overall expenses of the organizations.

With all these challenges in place, organizations need to be strategically organized to manage this volatile demand with minimal cost impacts and distribution delays. In certain cases, certain organizations also are planning for have both inventory buffers to reduce supplier & manufacturer delays and capacity buffers to increase production for order spikes. They also collaborate with contract manufacturers to outsource a part or total of their manufacturing processes to fasten the time to market or built-up stock. In other words, organizations are looking at strategies to reduce cycle times.

We talked of the problem statement and the traditional approach of how we look at these problems and their resolution techniques, but the major change that has come in and impacted the whole ecosystem is rethinking supply chain as the value driver and the key being the competitive differentiator. We previously had the legacy approach i.e. core to customer in which factories was the key adjustment parameter. It is important that companies shift from it to the supply chain platform i.e. customer to core where the key adjustment parameter shifted from factories to customer markets. In this, we setup a client-centric supply chain to focus on outbound supply and modularize the whole cycle from planning, procurement, manufacturing, sales and delivery into a platform centric approach thus enabling easy and efficient approach to problem solving and bottleneck reductions.

Now the question that comes up, Is your organization already on the platform centric track and are deriving benefits out of it or still gauging on the ways to move in. A digital transformation may help you in this regard and if we can go to the level of digital expansion, that would enable you to take advantage of the new technological advances in order to reduce supply chain volatility risks.