AI-driven solutions can address key challenges in semiconductor supply chains, enhancing visibility, scalability, and efficiency to meet growing demand and geopolitical complexities.

Insights

- AI enhances operational efficiency through predictive maintenance, improving demand forecasting, procurement, and customer interactions, driving smarter decisions.

- AI predicts supply-demand mismatches, enabling early identification of issues and short-term allocations, fostering proactive supply chain management.

- AI tools assist in managing revenue despite demand volatility and supply variability, crucial for adapting to market fluctuations.

- By predicting yield rates and lead times, AI refines planning accuracy and enables better resource allocation in semiconductor manufacturing.

- Leveraging an AI framework across semiconductor supply chains automates processes, improving efficiency and scalability in critical areas like inventory and demand management.

The semiconductor industry is one of the most complex and technologically advanced sectors, characterized by intricate supply chains, high-precision manufacturing processes, and rapid innovation cycles. Artificial intelligence, the Internet of Things, and 5G technologies are fueling the continuous rise in semiconductor demand. Billions are fueling the AI chip boom, propelling the industry towards a projected $1 trillion market by the end of the decade. Even though semiconductor industry executives expect to add 115,000 new semiconductor-related jobs in 2030 and invest in talent development, 67,000 of those will go unfilled.

While grappling with increased and fluctuating demand, the industry faces immense challenges due to geopolitical changes, complex supply chains, and limited visibility across global operations. Can AI-enabled semiconductor supply chains be the solution to some of the key challenges semiconductor supply chains are facing? How can AI-related solutions be dynamically scaled through a semiconductor supply chain?

This paper outlines an approach to identify and implement AI solutions in semiconductor supply chains, leveraging insights from industry successes. It also presents an approach to scale business benefits from AI implementations in semiconductor supply chains.

Key challenges in semiconductor value chains

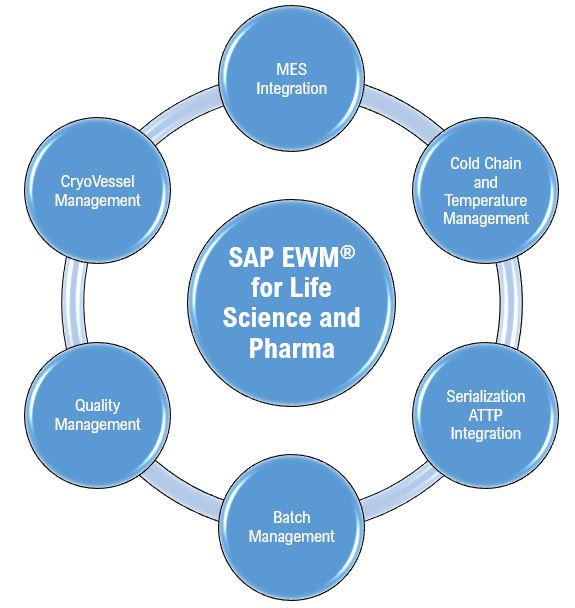

The semiconductor value chain faces challenges, including demand forecasting, balancing customization vs. standardization, talent shortages, aftersales logistics, and tool integration, as detailed in Figure 1. AI offers promising solutions to mitigate these issues, enhancing efficiency and driving smarter decision-making throughout the process. AI applications have proven successful in semiconductor design and R&D and have become a critical enabler of operational efficiency. Additionally, AI plays a pivotal role in creating resilient supply chains and delivers significant business value by optimizing processes, enhancing decision-making, and ensuring better adaptability to market fluctuations and disruptions.

AI in semiconductor manufacturing supply chain

AI is transforming semiconductor manufacturing by optimizing critical processes throughout the value chain. From improving forecasting accuracy and streamlining procurement decisions to enhancing operational efficiency with predictive maintenance, AI helps drive smarter, faster decisions. It also refines customer interactions through advanced analytics, improving lead management and overall sales effectiveness. Figure 2 highlights the key areas within the semiconductor manufacturing supply chain where AI can deliver substantial business impact and value.

Depending on the level of knowledge maturity in these areas for decision-making, selected AI capabilities are being explored through specific use cases. Features of these potential applications are evaluated against their expected business value, current process and technology maturity level (a measure of ease of implementation), and domain knowledge required (talent requirements),

Business value analysis involves assessing potential increases to revenue and margins, cost reductions, improved productivity, and new capability dimensions that are not possible with current technologies.

Current process and technology maturity analysis considers the availability of current tools, whether embedded or available as bolt-on solutions, as well as capabilities currently applicable in relevant industry segments or parallel industries, such as retail, precision manufacturing, hi-tech, or pharmaceuticals.

Domain knowledge measures the level of human intervention and know-how required to train the AI with business rules and manage constraints, despite machine learning models and approaches. A high-human-intervention situation means the AI has low domain knowledge and needs more training.

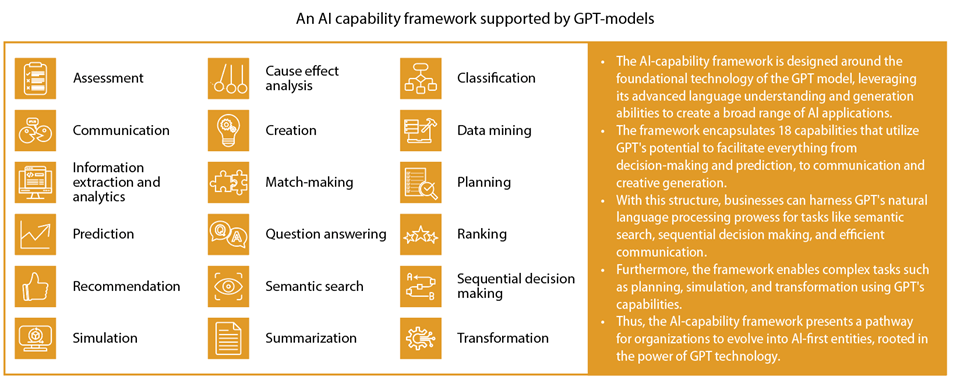

Apart from these core areas of AI applications, an AI framework model has been reviewed to assess its potential for layering on specific end-to-end (E2E) business processes within the supply chain. The assessment focuses on identifying tasks that can be automated or auto-decisioned using AI.

Other key areas for AI exploration in semiconductor supply chains include the following abilities:

1. Managing revenue every quarter with demand volatility and supply variability.

2. Synchronizing material, product, and resource availability between front-end and back-end operations, suppliers and contract manufacturers, and core customers and channel customers.

3. Predicting or sensing supply-demand mismatches ahead based on key indicators and pursuing short-term allocations.

4. Predicting yield rates and lead times for more accurate planning.

In addition, Infosys’s AI capability framework is also applicable to E2E supply chain processes (Figure 1).

Figure 1. An AI capability framework supported by GPT models

Each company, based on the type of tools it has, the domain knowledge, and the human intervention required, can assess the applicability of specific AI tools for its functional areas.

But how to transform a semiconductor supply chain?

Adopting and transforming a semiconductor supply chain toward AI requires careful planning, adequate resources, and a clear roadmap.

1. Pilot with use cases in specific domain areas

Identify areas with measurable return on investment (ROI). For example, demand forecasting or inventory management within the planning domain, and generate specific use cases to pilot as AI projects to test feasibility and refine models.

2. Leverage data availability

With vast amounts of data in semiconductor manufacturing organizations, create a centralized data repository and manage and monitor data quality. If multiple data sources and systems are present, evaluate the quality and integrity of the data and ensure a scalable platform is available to manage it. This also helps assess data and process gaps that are required to be addressed to enable an AI solution.

3. Collaborate with technology partners and generate an AI ecosystem

The ability to manage both domain knowledge and generate data analytics and machine learning models may require a variety of skill sets. Evaluate the strengths of the semiconductor manufacturing firm and accordingly partner with AI solution providers, cloud vendors, and analytics firms to accelerate AI adoption. For example, Qualcomm collaborates with AI startups to enhance its supply chain capabilities.

4. Integrate AI with existing systems

AI tools should be seamlessly integrated into existing ERP, MES, and SCM systems. This ensures that AI outputs align with business workflows.

5. Focus on a dynamic operating model and talent development

Depending on the domain area, know-how may be embedded in people’s skills and minds, in the process, or in technology and tools. Depending on the domain, embrace a dynamic operating model approach with processes, people, tools, and data as the four pillars of the model. For developing talent, build an in-house AI team by training supply chain professionals in AI technologies or hiring AI experts familiar with supply chain challenges and training them on supply chain processes.

AI has the potential to revolutionize the semiconductor supply chain by enhancing efficiency, reducing costs, and improving decision-making. However, the successful implementation of AI requires a strategic approach, including data integration, talent development, collaboration with ecosystem partners, and iterative development. While challenges such as data privacy, integration with legacy systems, and change management exist, they can be mitigated through robust cybersecurity measures, phased integration, and effective change management strategies. The semiconductor industry can draw parallels from other industries that have successfully implemented AI in their supply chains. Leading semiconductor manufacturers like Intel, TSMC, Samsung, Qualcomm, and NVIDIA are already leveraging AI technologies to optimize their supply chain operations and stay competitive in a rapidly evolving market. As AI continues to advance, its role in the semiconductor supply chain will only grow, driving innovation and creating new opportunities for value creation.