Introduction

The energy industry faces many challenges and opportunities due to the changing energy demand landscape, driven by factors such as geopolitics, macroeconomics, policies, regulations, and technologies. How can the industry overcome these challenges and seize these opportunities? As companies shift towards cleaner energy, the need to manage the assets efficiently becomes important. A key play that can tilt the game in favor of the player will be the ones who have got their digital twin implementation right. This can happen only by enhancing the engineering / asset information management (EIM) processes, which is crucial for boosting operating efficiency, reducing costs, improving safety, ensuring data security, and increasing data quality.

In this two-part article, we’ll discuss how oil and gas industry can prepare for the future by implementing an effective framework for asset / engineering information management (EIM).

Challenges in Managing Engineering and Asset Information

Managing and harnessing the large amount of data effectively is a significant challenge for businesses, especially when it comes to the sharing of information across different departments and teams. Furthermore, a lack of standardization in information management systems and practices can lead to data silos and duplication of efforts. A Gartner study has revealed that 47% of employees struggle to find the right information to perform their work. A worker struggling in searching for asset critical data poses risk on asset safety and performance.

The co-existence of different software for enterprise management (SAP, CRM, Document Management, etc.) and plant software (CMMS, PI, Inspection Data Management System, etc.) to perform overlapping functions leads in delays, data inconsistency, manual overheads etc. According to a report by PwC, only 18% of oil and gas companies believe that their data integration capabilities are advanced.

It is not uncommon to see the existence of two extremes within the same company – a region or division still using physical documents of assets while another division is trying to implement digital twin solutions. This “digital paradox” leads to shortfalls often not arising from technological capabilities but due to lack of standard practices in implementing technological programs.

As the energy industry shifts towards large scale renewable energy, the need for transforming the asset lifecycle management capabilities becomes even more important. Companies who have mastered new capabilities in asset information management will sustain in the long game.

The answer to these challenges is to apply first principles thinking while building solutions. What are we absolutely sure is true?

- Argument 1: There is a need for one system to create, update and retrieve asset information and documents.

- Argument 2: There is willingness to learn new things if it improves their work quality.

- Argument 3: Not everyone can afford to master systems and tools of different practices.

These self-evident truths along with the challenges that we know exist should be enough to convince that the important components to focus for mastering EIM capabilities are:

- Break down the silos – Develop a consistent approach for standardizing, migrating and enriching engineering information (documents, drawings, tags etc.)

- Integrate information with processes – Create a connected ecosystem where data flows seamlessly within the enterprise

The final objective off all these is to

- Develop analytics and presentation layer for a virtual replica.

Break down the silos

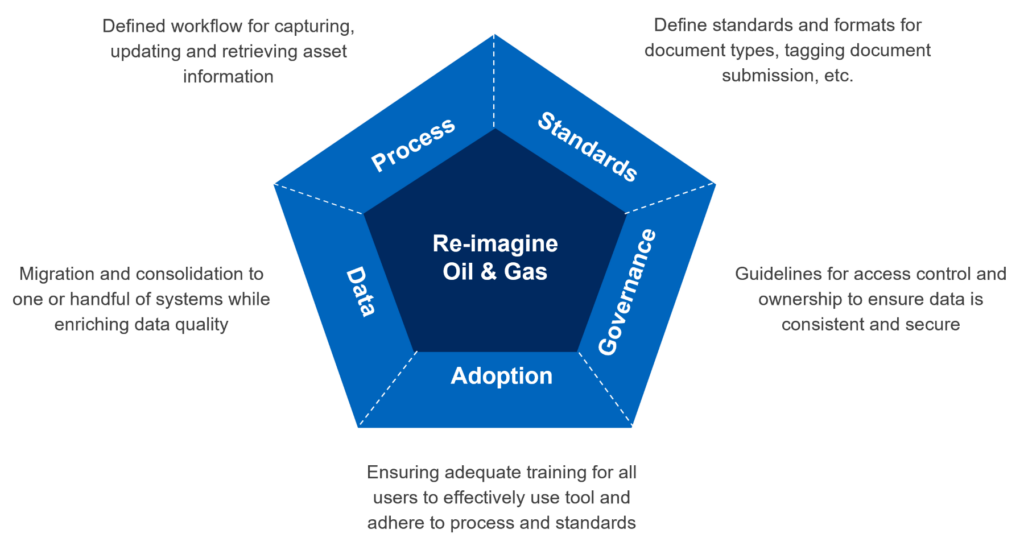

Managers responsible for drafting vision can leverage the “ElM Pentagon” framework to define where the organization should be in each of the 5 dimensions. The aspirational state for each of these dimensions should be something similar to what is mentioned below.

Process

The end state of a fully matured system would be well-defined processes for data creation and updation, known procedure and standards for data entry, dedicated workflows for document submission, tracking mechanism for projects and transmittals, and a robust change management process with separate workflows for design changes, maintenance updates, audit reviews etc. All these workflows will be powered by automation.

Standards

An acceptable convention for naming or numbering documents, drawings, tags, procedures must be adopted. Templates and Formats for all document types and pre-filled forms for document creation and updation for ensuring compliance to industry standards is in-place. A robust search criteria and indexing mechanism for every record entered to ensure easy retrieval of documents exists.

Data Migration and Quality

There should be a clear data consolidation / data migration strategy to have one or manageable number of systems. A partnership with vendors to digitalize all physical and scanned documents will ensure all assets have a complete digital record. A very high quality of indexing is achieved by scraping all asset information such as equipment tags, line numbers from documents and drawings. A CoE team as a guardian of best practices and technology will not only introduce digital tools for implementing these initiatives but also assure efficient implementation of all data migration and data transformation activities.

Governance

All roles with responsibilities are clearly defined and assigned for managing various aspects of asset information. There are data owners based on asset types for each region responsible for data quality; and data stewards for managing data at granular level. The approval workflows for access management with role-based access levels on each functionality is well-defined and change controlled. Bots and digital tools have been successfully deployed to ensure compliance with data polices and resolution of data-related issues.

Technology Adoption

A comprehensive training program exists to ensure users use the tool effectively. User manual, videos, onboarding guide for new users of varying comprehension is available for all tools and in-person workshops are regularly organized for new tools deployment. A DevOps team exists to provide the necessary support system to sustain these initiatives. Digital first approach to all these initiatives will help in creating highly personalized content and reduce cost of long-term trainings.