Introduction

Personalization means tailoring content based on user characteristics within predefined segments. Hyper-personalization is the advanced way to provide highly specific and relevant recommendations or content to each individual based on real-time data analysis and granular user data. This level of personalization can be achieved using data analytics, artificial intelligence(AI), and machine learning (ML). These technologies allow businesses to gather, analyze, and apply vast amounts of data from various sources like browsing history, past purchases, and social media activities and allows to create a customer experience that is unique to an individual. Hyper-personalization became an emerging trend in marketing and customer experiences due to various factors. These factors include technological developments, increasing importance of social media and digital channels, consumer demand for personalized experiences, and the widespread use of AI and machine learning in marketing and customer experience strategies. Another reason for the rise of hyper-personalization is the growing demand from consumers for more relevant and useful interactions with brands. Due to the huge amount of information and options available online, customers today demand experiences tailored to their particular needs and preferences. As digital marketing becomes more competitive, hyper-personalized marketing provides the opportunity for organizations to meaningfully engage customers, deepen existing relationships and build new ones, and improve the customer experience. Implementing this type of strategy not only increases customer satisfaction but also drives brand loyalty, willingness to spend, and overall marketing effectiveness.

Hyper-personalization in the manufacturing industry involves tailoring products, services, and experiences to meet the unique needs and preferences of individual customers. Artificial Intelligence (AI) plays a crucial role in achieving hyper-personalization by leveraging data, analytics, and automation. Here are several ways AI can bring hyper-personalization to the manufacturing industry:

- Customer Data Analysis:

- AI can analyze vast amounts of customer data, including historical purchases, preferences, and behavior, to gain insights into individual preferences.

- Predictive analytics can be employed to anticipate customer needs and trends, enabling manufacturers to proactively offer personalized solutions.

- Predictive Maintenance:

- AI-driven predictive maintenance systems can monitor equipment and machinery conditions in real-time.

- By predicting when a machine is likely to fail, manufacturers can schedule maintenance at optimal times, reducing downtime and improving overall efficiency.

- Supply Chain Optimization:

- AI can optimize the supply chain by predicting demand patterns, helping manufacturers maintain optimal inventory levels.

- This ensures that products are available when needed, reducing lead times and improving customer satisfaction.

- Smart Manufacturing and IoT:

- IoT devices connected to manufacturing equipment can collect real-time data on performance and quality.

- AI algorithms can analyze this data to identify patterns and optimize manufacturing processes for individualized products.

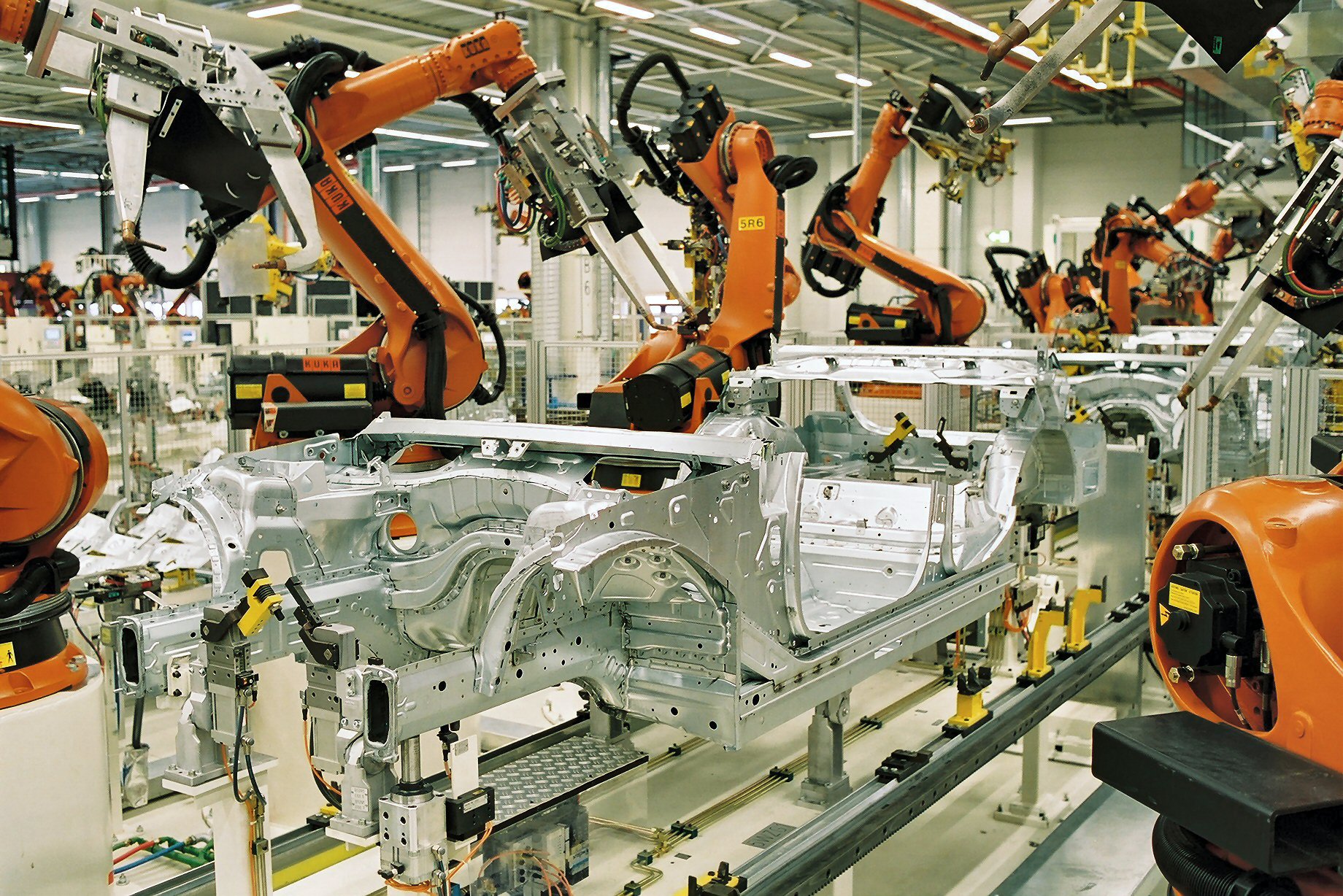

- Collaborative Robots (Cobots):

- Cobots, working alongside human workers, can facilitate the production of customized items. AI-powered robots can adapt to specific tasks and collaborate with human operators to achieve a more flexible and personalized manufacturing environment.

- Digital Twin Technology:

- Creating digital twins of products allows manufacturers to simulate and analyze various customization options before actual production begins. This helps in identifying the most efficient and cost-effective way to produce personalized items.

- Customization in Production:

- AI-powered robotic systems can facilitate flexible and efficient customization in production lines.

- This allows manufacturers to produce highly personalized products at scale, adjusting specifications based on individual customer requirements.

- Chatbots and Virtual Assistants:

- AI-powered chatbots and virtual assistants can provide personalized customer support, addressing queries, and guiding customers through product customization options.

- Natural Language Processing (NLP) enables these systems to understand and respond to individual customer inquiries.

- 3D Printing and Additive Manufacturing:

- AI can optimize 3D printing processes, enabling the creation of highly customized and complex products.

- This technology allows for on-demand production of personalized items with reduced waste.

- Quality Control and Assurance:

- AI can enhance quality control by detecting defects and variations in real-time during the manufacturing process.

- This ensures that personalized products meet high-quality standards.

- Augmented Reality (AR) for Customization:

- AR applications can be used to visualize and customize products in real-time.

Customers can use AR to see how personalized features will look before making decisions, enhancing their experience.

- AR applications can be used to visualize and customize products in real-time.

- Continuous Learning and Adaptation:

- AI systems can continuously learn from customer interactions, feedback, and market trends to adapt and improve personalization strategies over time.

Conclusion

Implementing AI-driven strategies can help manufacturers create a more agile, customer-centric, and efficient production process, leading to hyper-personalized offerings in the manufacturing industry.