The Dawn of Conversational Robots

Imagine walking into a factory and saying to a robot, “Check if all the screws on that assembly line are properly tightened,” and the robot not only understands you but actually does it. This isn’t science fiction anymore—it’s the reality emerging from the convergence of Large Language Models (LLMs) and robotic control systems.

Large Language Models are transformer-based neural networks trained on massive text corpora (often 100+ billion parameters) that can understand and generate human language with remarkable sophistication. Models like GPT-4, Claude-3, and LLaMA-2 represent the current state-of-the-art in natural language processing, utilizing attention mechanisms and deep learning architectures to process contextual information. When we integrate these language models with robotic systems—combining natural language understanding with computer vision, sensor fusion, and autonomous control algorithms—we create a paradigm shift: robots that can interpret human intentions through conversational interfaces and translate them into precise physical actions.

Breaking Down the Tech (In Simple Terms)

What Makes LLMs Special?

Large Language Models utilize transformer architectures with self-attention mechanisms that enable them to process sequential data and understand contextual relationships across long input sequences. Unlike traditional rule-based systems or simpler neural networks, LLMs employ:

- Multi-head attention layers: that capture different types of relationships within the input text

- Positional encoding: to understand word order and sequence structure

Gradient-based fine-tuning: capabilities for domain-specific adaptation - In-context learning: that allows them to adapt to new tasks without parameter updates

- Chain-of-thought reasoning: enabling step-by-step problem decomposition

The key breakthrough is their ability to perform few-shot and zero-shot learning—understanding new tasks with minimal or no specific training examples.

Why Traditional Robots Fall Short

Traditional industrial robots operate on deterministic control systems with pre-programmed instruction sets. They rely on:

- Fixed control algorithms: (PID controllers, state machines) that cannot adapt to unexpected

- Rigid sensor-to-action mappings: that require extensive manual programming for each

- Limited environmental understanding: through basic sensor inputs (force, position, vision) without semantic interpretation

- Lack of contextual reasoning: making them unable to handle ambiguous commands or dynamic environments

For example, a traditional robot programmed to “pick up the red box” would fail if presented with multiple red objects or if the lighting conditions change the perceived color—it lacks the semantic understanding to disambiguate based on context.

The Game-Changing Combination: LLM-Robot Integration Architecture

The integration of LLMs with robotics creates a sophisticated multi-modal system architecture:

Natural Language Processing Pipeline: The system employs tokenization, embedding layers, and transformer attention mechanisms to convert human speech into semantic representations. Speech-to-text models (like Whisper) first convert audio to text, which is then processed through the LLM’s encoder-decoder architecture.

Semantic-to-Action Translation: The LLM output undergoes semantic parsing to extract actionable parameters. For example, “inspect the welding joints on the car doors” gets decomposed into:

- Task type: Visual inspection

- Target object: Welding joints

- Location context: Car doors

- Quality criteria: Joint integrity, penetration depth, surface finish

Robotic Control Integration: The semantic understanding is translated into robotic commands

- Motion planning algorithms: (RRT*, A*) for path generation

- Computer vision pipelines: using CNN-based object detection and pose estimation

- Sensor fusion: combining RGB-D cameras, force sensors, and IMUs

- Real-time control loops: executing planned trajectories with feedback correction

Learning and Adaptation: The system implements reinforcement learning from human feedback (RLHF) to improve performance over time, storing successful interaction patterns in vector databases for future reference.

Revolutionary Impact on Quality Assurance

The Current QA Challenge

Quality assurance in manufacturing is like being a detective—you need to spot problems, understand their causes, and make decisions about whether products meet standards. Traditional approaches require:

• Highly trained human inspectors who can get tired or miss details

• Rigid inspection checklists that can’t adapt to new situations

• Time-consuming manual documentation

• Difficulty in scaling up when production increases

How LLM-Powered Robots Transform QA

1.Multi-Modal Intelligent Inspection Systems

LLM-integrated inspection systems combine computer vision with natural language understanding:

- Vision-Language Models (VLMs): like CLIP or DALL-E variants enable robots to generate textual descriptions from visual inputs: “Surface defect detected: linear scratch, 2.3mm length, 0.1mm depth, oriented 15° from horizontal axis”

- Semantic segmentation algorithms: identify specific regions of interest with pixel-level accuracy

- Defect classification models: trained on domain-specific datasets can categorize anomalies with confidence scores

- Natural language report generation: using template-based or generative approaches to create human-readable inspection summaries

2. Dynamic Quality Standard Adaptation

The system implements adaptive quality control through:

- Few-shot learning protocols: that allow rapid adaptation to new product specifications

- Prompt engineering techniques: for encoding quality standards into natural language templates

- Knowledge graph integration: linking product specifications, defect types, and acceptance criteria

- Real-time parameter adjustment: through conversational interfaces that update inspection algorithms

3. Predictive Analytics and Root Cause Analysis

Advanced LLM systems provide:

- Time-series analysis: of quality metrics using LSTM or transformer-based forecasting models

- Anomaly detection algorithms: (Isolation Forest, Autoencoders) for identifying unusual patterns

- Causal inference engines: that correlate environmental factors with defect rates

- Natural language explanation generation: for complex quality trends

4.Human-Robot Collaborative Interfaces

The system architecture supports:

- Multi-turn dialogue management: with context preservation across conversations

- Intent recognition and slot filling: for parsing complex quality-related queries

- Real-time data visualization: triggered by natural language requests

- Escalation protocols: for critical issues requiring human intervention

Real-World Implementation: Technical Case Studies

NVIDIA’s GR00T N1 and Blue Robot Architecture

NVIDIA’s Blue robot represents a significant advancement in embodied AI, implementing:

• Foundation Model Architecture: Built on the GR00T N1 transformer model with 7B+ parameters specifically trained for robotic applications

• Physics-Informed Training: Utilizes NVIDIA’s Newton physics engine for realistic simulation-based learning

• Dual-System Cognitive Architecture:

– System 1 (Fast): Reactive control using lightweight neural networks for real-time responses

– System 2 (Slow): Deliberative planning using the full LLM for complex reasoning tasks

• Multi-Modal Sensor Fusion: Integrates RGB-D cameras, IMUs, force/torque sensors, and proprioceptive feedback

• Real-Time Inference: Optimized for edge deployment with TensorRT acceleration and quantization techniques

Technical specifications include sub-100ms response times for simple commands and sophisticated motion planning capabilities that demonstrate human-like fluidity in movement.

Industrial QA Implementation: Automotive Case Study

A leading automotive manufacturer implemented LLM-powered QA systems with the following technical stack:

Hardware Configuration:

• Industrial robot arms (6-DOF) with 0.1mm repeatability

• High-resolution machine vision systems (4K RGB + depth sensors)

• Edge computing nodes with GPU acceleration (NVIDIA Jetson AGX Orin)

• Distributed sensor network with real-time data streaming

Software Architecture:

• Perception Pipeline: YOLOv8-based object detection with custom-trained models for automotive components

• LLM Integration: Fine-tuned LLaMA-2 model with automotive domain knowledge

• Quality Database: Graph database (Neo4j) storing relationships between defects, causes, and solutions

• Control Systems: ROS2-based distributed architecture with real-time constraints

Performance Metrics:

• Defect detection accuracy: 99.2% (vs 94% human baseline)

• False positive rate: <2%

• Inspection throughput: 300% increase over manual processes

• Mean time to adaptation for new products: 4 hours (vs 2 weeks traditional programming)

Technical Implementation and ROI Analysis

Computational Requirements and Optimization:

• Model inference optimization through techniques like quantization (INT8/FP16) and pruning

• Edge deployment strategies balancing latency vs. accuracy trade-offs

• Distributed computing architectures for handling multiple concurrent inspection streams

• Memory management for large vision-language models in resource-constrained environments

Cost-Benefit Analysis:

• Capital Expenditure: Initial robot deployment costs range from $150K-$500K per unit depending on complexity

• Operational Savings: 60-80% reduction in labor costs for quality inspection

• Quality Improvements: Defect escape rate reduction from 2-3% to <0.5%

• Scalability Economics: Marginal cost per additional robot decreases significantly in multi-unit deployments

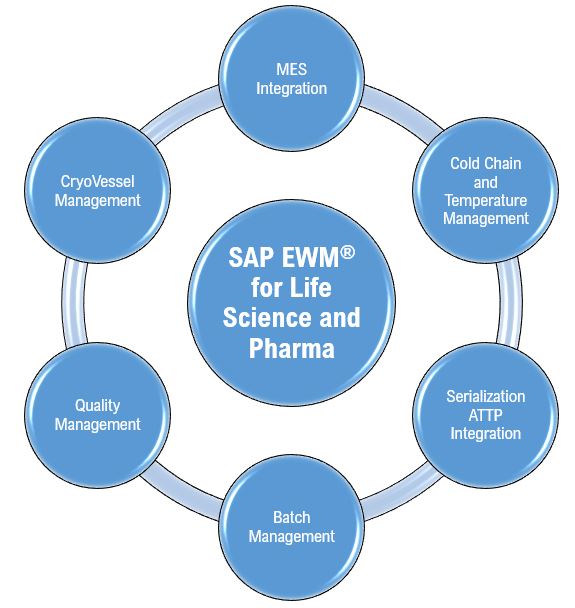

Integration Challenges and Solutions:

• Legacy System Compatibility: API development for interfacing with existing MES/ERP systems

• Network Infrastructure: Requirements for low-latency communication and data synchronization

• Cybersecurity: Implementation of secure communication protocols and data encryption

• Compliance: Meeting industry standards (ISO 9001, FDA 21 CFR Part 11) for regulated environments

Technical Challenges and Risk Mitigation

Safety-Critical System Design

LLM-powered robotic systems require robust safety architectures:

• Formal Verification Methods: Mathematical proofs of system behavior within defined operational boundaries

• Hierarchical Safety Controls: Multiple layers of safety systems from hardware emergency stops to software-based constraint verification

• Uncertainty Quantification: Bayesian approaches to measure confidence in LLM outputs and trigger human oversight for low-confidence scenarios

• Fail-Safe Mechanisms: Default behaviors that ensure safe system states when unexpected conditions arise

Addressing LLM Limitations in Industrial Contexts

• Hallucination Mitigation: Implementation of retrieval-augmented generation (RAG) systems with verified knowledge bases

• Domain Adaptation: Fine-tuning strategies using industrial-specific datasets and terminology

• Temporal Consistency: Maintaining coherent behavior across extended operational periods

• Robustness to Input Variations: Handling noisy speech, technical jargon, and incomplete commands

Future Research Directions and Emerging Technologies

Advanced AI Architectures:

• Multimodal Foundation Models: Integration of vision, language, and robotic control in unified architectures

• Federated Learning: Distributed training across multiple robotic systems while preserving data privacy

• Continual Learning: Algorithms that enable robots to learn new tasks without forgetting previous knowledge

• Neurosymbolic AI: Combining neural networks with symbolic reasoning for better interpretability and reliability

Conclusion: The Technical Transformation of Quality Assurance

The integration of Large Language Models with robotic systems represents a fundamental paradigm shift in industrial automation—from deterministic, pre-programmed systems to adaptive, intelligent agents capable of natural human interaction. This transformation is enabled by several key technological convergences:

Architectural Innovation: The combination of transformer-based language models with modern robotic control systems creates unprecedented flexibility in human-machine interaction while maintaining the precision required for industrial applications.

The fusion of LLMs and robotics marks a pivotal moment in the evolution of intelligent machines. By allowing robots to interpret and act upon human language, LLMs enable a new era of seamless interaction between humans and machines. The future holds exciting possibilities as this technology continues to mature, with robots becoming not just tools, but collaborative partners in our everyday lives.