Executive Snapshot

As AI-assisted decision preparation moves into live supply-chain workflows, the binding constraints shift from model capability to execution design, governance discipline, and integration maturity. Early deployments show that accelerating decisions without explicit controls exposes organizations to new forms of operational risk, including opaque authority, cascading execution errors, and fragile coordination across legacy systems and partners. Value materializes only where AI outputs are deliberately structured for execution, bounded by approval thresholds, and embedded within auditable workflows that preserve accountability. At this stage, adoption is less a technology challenge than an engineering and control problem, where design choices determine whether speed compounds advantage or amplifies exposure.

How Generative and Agentic AI Are Executed in Supply Chain Operations

In current supply-chain deployments, generative and agentic AI are being used primarily to prepare and coordinate execution, not to replace core planning systems or human authority. Operational value is being created where these technologies reduce the time and effort required to move from a detected issue to an approved action across logistics, procurement, and inventory workflows.

The distinguishing feature of these deployments is not model sophistication, but tight coupling between AI outputs and execution workflows within existing enterprise systems.

Execution model observed in practice

Across validated deployments, a consistent execution model has emerged.

- Operational data from enterprise systems is first made accessible to the AI layer so that recommendations reflect the current state of orders, inventory, shipments, and partner interactions. This grounding ensures that outputs are relevant to live operating conditions rather than generic assumptions.

- Based on this context, the system prepares execution-ready outputs. These outputs are not informal suggestions, but structured recommendations such as draft purchase orders, booking options, rerouting proposals, or exception-resolution steps. The intent is to minimize manual interpretation and rework.

- An orchestration or middleware layer is then used to translate these prepared outputs into system-compatible actions. This layer enforces policy constraints, manages approvals, and ensures that actions are logged and auditable. Execution is either staged for rapid human approval or carried out automatically within predefined limits.

This execution model has been preferred over direct automation, as it preserves accountability while materially reducing response time.

Agentic execution for multi-step coordination

Agentic AI extends this model by supporting sequenced operational workflows rather than isolated recommendations.

In validated pilots, agents are configured to continuously monitor operational signals such as shipment delays, port congestion, or supplier updates. When a threshold is reached, the agent prepares a sequence of follow-up steps – for example, identifying alternatives, assessing cost and service trade-offs, and preparing execution artifacts – while stopping at defined checkpoints for human approval.

This approach reduces repeated manual coordination across teams without removing decision authority. As a result, agentic execution remains deliberately bounded and supervised in supply-chain contexts.

Execution examples from supply-chain operators

Public disclosures from large operators illustrate how this execution model is being applied.

- DHL Supply Chain has announced the deployment of generative AI to support data management and customer proposal preparation. The initiative was positioned as a staged rollout, beginning with document- and data-intensive workflows. This approach reflects how execution capability is being built incrementally, using low-risk processes before expanding toward decision-oriented use cases.

- DB Schenker has launched its Ocean Bridge solution, combining real-time container visibility with AI-based forecasting to improve shipment-level planning certainty. The solution is intended to enable earlier operational decisions by providing planners with actionable visibility at the container level, rather than post-event analysis.

- Maersk has described the application of advanced analytics and generative techniques to routing and operational planning. These initiatives incorporate factors such as weather, safety, and energy considerations to inform execution decisions in vessel and port operations, demonstrating how AI outputs are being linked to real operational adjustments.

- Amazon has publicly detailed the use of large-scale AI models to improve inventory placement, fulfilment efficiency, and delivery operations. In addition, Amazon has reported operational improvements where AI outputs are tied directly to robotic routing and execution in warehouses, illustrating integration between AI reasoning and physical execution systems.

These examples share a common pattern: AI outputs are used to prepare and accelerate execution, not to replace operational control.

Measured execution signals (pilot-level)

Where these execution patterns have been applied, operators have reported directional improvements in operational readiness.

Reported outcomes include faster preparation of proposals and operational documents, improved shipment-level planning certainty, and earlier intervention in routing and fulfilment decisions. These results have been presented as pilot-level or product-specific outcomes rather than enterprise-wide guarantees.

Independent, large-scale benchmarking remains limited, and most reported benefits are framed conservatively as contextual improvements rather than universal performance gains.

Preconditions for effective execution

Validated sources consistently identify several prerequisites for execution-oriented deployments:

- Reliable and auditable access to core operational data

- Integration layers capable of translating AI outputs into system actions

- Clearly defined policy guardrails and approval thresholds

- A staged deployment approach, progressing from low-risk workflows to supervised decision preparation

- Where these foundations are absent, deployments tend to remain advisory and struggle to scale.

Practical implications for supply-chain leaders

Observed execution patterns suggest several implications:

- Generative and agentic AI deliver value when tied directly to execution workflows, not when deployed as analytical overlays.

- The strongest impact is seen where coordination time and decision latency are the primary constraints.

- Supervised execution models are being favored over autonomy due to governance, risk, and accountability considerations.

These realities explain why progress is most visible in logistics coordination, procurement support, and fulfilment operations, while broader automation remains cautious.

Where control, risk, and accountability are decided

At scale, the critical question is not whether AI-generated recommendations are useful, but whether execution remains controllable, auditable, and resilient as decision preparation accelerates. When generative or agentic systems prepare actions that flow directly into operational systems, governance failures manifest as operational incidents rather than analytical errors, increasing the blast radius of mistakes. Without explicit approval thresholds, ownership of orchestration logic, defined escalation paths, and continuous monitoring for drift and degradation, organizations risk concentrating decision authority in opaque mechanisms that erode accountability and trust. AI-enabled execution is therefore viable only where control mechanisms are engineered with the same rigor as speed, ensuring that acceleration does not outpace the organization’s ability to intervene, explain outcomes, and recover.

Constraints, Failure Modes, and Second-Order Risks

While generative and agentic AI are beginning to show execution-level value in supply chain operations, adoption is constrained by a set of structural, operational, and systemic risks. These risks are not theoretical. They have been identified through early deployments, industry surveys, and public disclosures by large operators and technology providers.

Structural constraints limiting scale

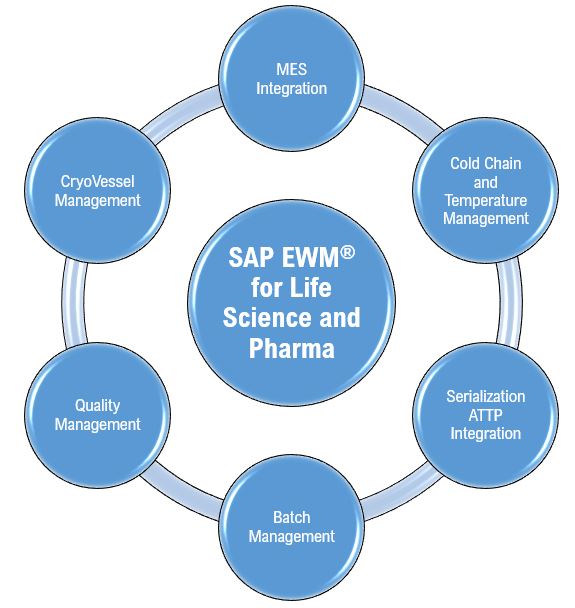

- The most frequently cited constraint is data integration and data gravity. Generative and agentic systems depend on reliable, auditable access to data from ERP, TMS, WMS, control towers, and partner systems. In practice, this access is often fragmented across legacy platforms, business units, and external partners. Industry research consistently identifies data integration and governance as the primary bottleneck in moving from pilot to production.

- A related constraint is partner data availability. Supply chains operate across multiple legal entities, and contractual limits on data sharing with suppliers, carriers, and logistics partners restrict how much operational context can be provided to AI systems. This limits grounding quality and reduces the reliability of execution-level recommendations.

- Cost and infrastructure overhead also emerge as constraints. Inference costs, integration engineering, and cloud egress charges materially affect total cost of ownership. These costs are often underestimated during pilots and become visible only when transaction volumes increase.

Governance and operational control challenges

Generative and agentic AI introduce new governance challenges because they operate at the boundary between analysis and execution.

Research shows that organizations which fail to define clear human-validation thresholds struggle to scale. Without explicit rules governing when human approval is mandatory, operational risk increases and trust deteriorates. High-performing adopters formalize approval tiers based on financial exposure, service impact, and reversibility.

Shadow AI usage presents an additional control risk. Employees using unsanctioned generative tools for operational tasks can inadvertently expose sensitive data or bypass established controls. Industry analysts have flagged this as a growing enterprise risk, particularly in data-rich operational functions such as logistics and procurement.

Observed failure modes in early deployments

Several failure modes have already been documented or cautioned against by operators and analysts.

- One recurring issue is confident but incorrect execution preparation. Without strong data grounding, models can generate plausible but wrong outputs, such as incorrect booking details or invalid routing assumptions. This risk is amplified when outputs are structured for execution.

- Another failure mode is silent performance degradation. As operational patterns change due to seasonality, network shifts, or geopolitical events, model performance can drift without obvious signals. If monitoring is insufficient, systems may continue to recommend actions based on outdated assumptions.

- In agentic workflows, cascading execution failures are a specific risk. A single incorrect decision, when propagated across multi-step automated processes, can trigger downstream actions across multiple systems and partners, increasing the blast radius of errors.

- Finally, over-reliance on AI recommendations can lead to gradual erosion of human judgment. If planners become accustomed to accepting recommendations without scrutiny, recovery capability may weaken during outages or unexpected conditions.

Second-order and systemic risks

Beyond immediate operational risks, several second-order effects are emerging.

- Decision centralization is one such effect. As decision logic becomes embedded in centralized AI systems, local discretion can be reduced. This can create organizational resistance and reduce sensitivity to local context, particularly in global supply chains with diverse operating conditions.

- Vendor and model lock-in represents a strategic risk. As prompts, decision logic, and feedback loops become tightly coupled to specific foundation models and platforms, switching costs increase. Industry advisories recommend maintaining ownership of prompts, policies, and orchestration logic to preserve strategic flexibility.

- Another systemic concern is risk concentration. Centralized agentic systems can become single points of failure. Errors, outages, or cyber incidents affecting these systems may have disproportionate impact across networks, amplifying operational disruption.

- At the ecosystem level, widespread adoption of agent-assisted procurement or logistics decisioning may alter market behavior. As more participants adopt similar optimization strategies, early competitive advantages may erode, and pricing or capacity signals may become distorted.

Industry examples illustrating constraints and risks

Public disclosures highlight how leading organizations are managing these risks.

- DHL Supply Chain has emphasized a staged rollout approach, starting with document- and data-intensive tasks. This reflects an explicit attempt to manage governance, adoption, and operational risk before expanding into decision-critical workflows.

- DB Schenker, while introducing container-level visibility and AI-based forecasting through Ocean Bridge, continues to acknowledge dependence on partner data feeds. This underscores the persistent constraint of multi-party data sharing in global logistics.

- Maersk has highlighted the sensitivity of global operations to geopolitical and operational volatility. In such environments, centralized AI-driven decisions require careful design to avoid amplifying systemic shocks.

- SAP, from a platform perspective, has consistently emphasized retrieval, grounding, and auditability as prerequisites for safe execution-oriented AI, reinforcing the importance of governance-first architecture.

Mitigation patterns supported by evidence

Across validated sources, several mitigation patterns consistently appear:

- Formal human-validation engineering, with approval thresholds aligned to business impact

- Strong data governance and provenance, including partner access controls

- Staged deployment models, progressing from low-risk automation to supervised execution

- Ownership of prompts, policies, and orchestration layers to reduce vendor lock-in

- Continuous monitoring and drift detection, with rollback mechanisms for agentic workflows

Organizations applying these controls report greater confidence and durability in early deployments.

Practical implications for leaders

The evidence indicates that constraints and risks are not peripheral issues; they are central to whether generative and agentic AI can be operationalized responsibly.

Leaders should expect that:

- Scaling will be limited by data and governance readiness, not model capability

- Supervised execution will remain the dominant pattern in the near term

- Second-order organizational and ecosystem effects must be actively managed

Ignoring these realities increases the likelihood of stalled pilots, loss of trust, or operational incidents.

The Real Opportunity Ahead – and How Leaders Should Respond

The real opportunity with generative and agentic AI in supply chains does not lie in incremental automation or isolated pilots. It lies in restructuring how decisions are prepared, coordinated, and executed across the value chain. Evidence from industry surveys and early adopters indicates that competitive advantage will accrue to organizations that move beyond experimentation and deliberately redesign operating models, governance, and metrics around AI-augmented decision-making.

Market signals pointing to a narrowing window of advantage

Industry research shows a clear divergence forming between organizations that treat generative AI as a tactical tool and those that treat it as strategic infrastructure.

Surveys indicate that only a minority of supply-chain organizations currently operate with a formal AI strategy. At the same time, a material share of generative AI initiatives are expected to stall after proof-of-concept due to unclear business ownership, weak data foundations, and rising costs. This gap creates a near-term opportunity for leaders who can translate intent into disciplined execution.

Organizations that align AI investments with core business outcomes, rather than technology novelty, are more likely to scale successfully and capture early-mover benefits.

Where the next wave of value is expected to emerge

- One area is decision orchestration across functions. Instead of optimizing planning, procurement, and logistics independently, generative and agentic AI enable coordinated decision preparation across these functions. This creates compound benefits, such as reducing downstream expediting costs while improving service reliability.

- Another area is scenario-driven resilience. Generative models are increasingly used to simulate disruption scenarios that are not well represented in historical data. This allows organizations to test contingency playbooks and prepare execution responses in advance, improving recovery time during real events.

- A third opportunity lies in procurement acceleration and compliance. AI-assisted sourcing, contract drafting, and negotiation preparation reduce cycle times and free teams to focus on strategic supplier relationships rather than administrative work.

Evidence from industry leaders shaping the opportunity

- DHL has described the use of generative AI to support predictive demand insights, customs workflows, and procurement processes. These initiatives are framed as part of a broader effort to embed AI into operational execution rather than standalone analytics.

- A.P. Moller – Maersk has highlighted how advanced AI techniques can support warehouse operations, reorder strategies, and logistics planning. The focus is on improving execution quality and responsiveness in complex global networks.

- Industry research from McKinsey & Company indicates that organizations redesigning workflows around AI – rather than layering AI onto existing processes – are more likely to report material business impact. This reinforces the view that opportunity depends on operating-model change, not model capability alone.

Economic and workforce implications

The opportunity is not limited to cost reduction. Productivity studies show that AI-augmented roles can reclaim meaningful time for higher-value work, particularly in planning, coordination, and exception management. In supply-chain contexts, this translates into faster decision cycles and improved responsiveness under volatility.

Importantly, the evidence suggests that value is being realized through human–AI collaboration, not workforce replacement. Organizations that invest in role redesign, training, and clear accountability structures are better positioned to sustain gains.

How leaders should respond

- First, a formal AI strategy for supply chain should be established, linking use cases to business outcomes such as decision latency, cost avoidance, and service reliability. This reduces pilot fragmentation and clarifies investment priorities.

- Second, leaders should redesign decision workflows, not just deploy tools. This includes redefining who approves what, how exceptions are escalated, and where AI-prepared actions enter execution systems.

- Third, measurement must shift from model metrics to business metrics. Tracking forecast accuracy or model usage is insufficient; leaders should measure time-to-decision, recovery time after disruption, procurement cycle duration, and operational variance.

- Finally, data governance and integration should be treated as strategic assets. Organizations that invest early in data pipelines, lineage, and partner data-sharing frameworks are better positioned to scale AI-driven execution.

Conclusion

The long-term impact of generative and agentic AI in supply chains will be determined not by how fast decisions can be prepared, but by how safely they can be executed at scale. Without deliberate governance, ownership, and monitoring, AI-driven acceleration risks concentrating failure modes and eroding trust rather than improving resilience. Organizations that treat AI-assisted execution as critical infrastructure-designed with the same rigor as financial controls or safety systems-are more likely to sustain early gains, while those that prioritize speed over control may discover that faster decisions simply fail faster.

References

- https://group.dhl.com/content/dam/deutschepostdhl/en/media-relations/press-releases/2024/pr-dsc-implements-genai-20241024.pdf

- https://group.dhl.com/en/media-relations/press-releases/2024/for-increased-usability-and-efficiency-mydhli-meets-genai.html

- https://procurementmag.com/news/agentic-ai-propelling-procurement-forward

- https://www.dbschenker.com/global/insights/profile/press-releases/augmented-supply-chain-monitoring-solution-ocean-bridge-2467682

- https://www.deloitte.com/us/en/insights/topics/digital-transformation/four-emerging-categories-of-gen-ai-risks.html

- https://www.gartner.com/en/newsroom/press-releases/2024-07-29-gartner-predicts-30-percent-of-generative-ai-projects-will-be-abandoned-after-proof-of-concept-by-end-of-2025

- https://www.icrontech.com/resources/blogs/how-agentic-ai-is-shaping-supply-chain-planning-in-2026

- https://www.itpro.com/technology/artificial-intelligence/gartner-says-40-percent-of-enterprises-will-experience-shadow-ai-breaches-by-2030-educating-staff-is-the-key-to-avoiding-disaster

- https://www.maersk.com/insights/digitalisation/2024/01/03/how-can-generative-ai-drive-logistics-transformation

- https://www.maersk.com/insights/logistics-trend-map/artificial-intelligence-in-logistics

- https://www.reuters.com/business/over-40-agentic-ai-projects-will-be-scrapped-by-2027-gartner-says-2025-06-25/

- https://www.tandfonline.com/doi/full/10.1080/00207543.2024.2447927