In the evolving landscape of industrial automation, the integration of Operational Technology (OT) and Information Technology (IT) is already a reality, not merely a future certainty. One of the most transformative shifts is the integration of control systems into cloud platforms, often termed as “cloudification.” This transition is not just about remote access; it’s about enabling advanced capabilities like real-time analytics, model-based optimization, and digital twins that mirror physical systems with remarkable fidelity.

In this post, we’ll explore the process of cloudifying control systems and how this unlocks the full potential of digital twins across industries.

What Is Cloudification of Control Systems?

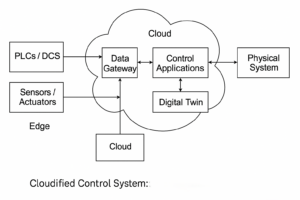

Cloudification refers to migrating or extending traditional control system functionalities—typically confined to on-premises PLCs, DCS, and SCADA—to cloud environments. This involves real-time data ingestion, secure gateways for OT-IT communication, cloud-hosted control logic, and integration with cloud-native services such as data lakes, AI/ML models, and digital twins.

Benefits of Cloud-Based Control Systems

• Scalability: Cloud platforms offer scalable resources, allowing control systems to handle varying loads efficiently.

• Cost Efficiency: Reduced capital expenditure on hardware and maintenance through pay-as-you-go models.

• Accessibility: Remote access to control systems from anywhere, facilitating real-time monitoring and control.

• Collaboration: Enhanced collaboration among teams through cloud-based tools and platforms.

• Automatic Updates: Regular software updates and maintenance handled by cloud service providers.

• Disaster Recovery: Robust backup and disaster recovery solutions ensuring data integrity and availability.

Block Diagram: Cloudified Control System with Digital Twin

Figure: Network architecture integrating a control system with cloud platforms for digital twin functionality.

The Integration Process

1. Edge Enablement: Deploying edge gateways that connect legacy PLCs/DCS systems to the cloud.

2. Data Modeling & Normalization: Standardizing raw data using semantic data models.

3. Cloud Pipeline Integration: Secure transmission of normalized data to cloud storage and compute services.

4. System Virtualization: Hosting services in the cloud to mirror process states and enable separation of logic.

5. API-Based Control Orchestration: Hosting control loops and decision logic in cloud APIs for flexible orchestration.

Digital Twins: The Crown Jewel of Cloudification

A digital twin constitutes a living, virtual representation of a physical asset, process, or entire system, continuously informed by real-time data from its control systems. With real-time control system data, digital twins enable predictive diagnostics, simulation, what-if analysis, lifecycle integration, and global scalability.

Real-World Use Cases

– Aerospace: Rolls-Royce uses digital twins of jet engines fed by control system telemetry.

– Energy: Digital twins of turbines optimize performance and emissions.

– Manufacturing: Smart factories employ digital twins for OEE, defect prediction, and closed-loop control.

Challenges & Considerations

– Latency: Critical control loops must still execute locally.

– Cybersecurity: Requires robust secure communication and OT-IT bridging.

– Data Governance: Strong policies for compliance, ownership, and access are essential.

Final Thoughts

Cloudifying control systems is not about replacing traditional automation—it’s about extending its reach and intelligence. Combined with digital twins, cloud architectures empower predictive, proactive, and optimized industrial operations.

Mini Case Study: Smart Water Treatment Plant

A UK-based utility modernized its filtration control system by connecting PLCs to AWS IoT Core and overlaying a digital twin. With continuous real-time data from sensors, the twin could simulate valve degradation under variable flow conditions. This enabled predictive maintenance scheduling and led to a 22% reduction in unplanned downtime over 12 months.

Digital Twin Lifecycle

The digital twin evolves through the following lifecycle stages:

– Design

– Deployment

– Integration

– Monitoring

– Simulation

– Optimization

– Continuous Learning

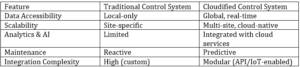

Comparison: Traditional vs. Cloudified Control Systems

Glossary

– **OPC UA**: Open platform communication for machine-to-machine interoperability.

– **Edge Gateway**: Hardware interface that connects OT devices to IT/cloud platforms.

– **Digital Twin**: serves as a continuously updated virtual representation of a physical system, enabling comprehensive simulation and analysis.

– **MQTT**: is a streamlined publish-subscribe messaging protocol, frequently employed in Internet of Things (IoT) applications due to its efficiency.”

Future Outlook

The cloudification of control systems offers transformative potential for industrial automation. While there are challenges to address, the benefits far outweigh the drawbacks. By leveraging cloud-based solutions, organizations can achieve greater scalability, cost efficiency, accessibility, collaboration, and disaster recovery. The future trends indicate a continued evolution towards more intelligent, flexible, and secure control systems.

With advancements in 5G, edge computing, and generative AI, digital twins will become capable of autonomous optimization and early-warning detection. Cloudified control systems will be the backbone of this evolution.

Futuristic visualization of a digital twin optimizing an industrial process autonomously

This is a fascinating and comprehensive overview of the cloudification of control systems and the role of digital twins in industrial automation