In today’s complex and advanced industrial landscape, managing assets efficiently ensuring regulatory compliance and maintaining system integrity is challenging and of great importance. Downtime can cripple production, and inefficient asset management can lead to cost overruns and compliance issues. This is where FactoryTalk AssetCentre comes into picture and fits in, offering a robust solution for managing and maintaining industrial assets.

What is FactoryTalk AssetCentre?

FactoryTalk AssetCentre, from Rockwell Automation is a centralized asset management software solution designed to centralize, organize, monitor, track, and secure the automation assets. It acts as a central nervous system for an industrial equipment, allowing you to track, manage, and optimize everything from PLCs and HMIs to drives, sensors, and other critical components. It ensures smooth running of the production systems while meeting the regulatory standards by providing comprehensive control over asset information and change management.

What Problems Does AssetCentre Solve?

Imagine below scenarios:

1. A critical PLC fails in one of the lines in the shop floor, and no one can find the latest program version. Production gets impacted and down while engineers are struggling to recover the lost code.

2. Audits reveal inconsistencies in software versions across the plant, leading to compliance issues and production delays.

3. Engineers/Techs spend valuable time searching for documentation, backups, and other critical information, slowing down repairs and significantly increasing the downtime.

FactoryTalk AssetCentre addresses these challenges by providing a centralized repository for all automation assets. It offers version control, change management, backup and restore capabilities, and comprehensive documentation tools, all within a secure and user-friendly environment.

Key Features and Benefits

- Version Control: Track changes to your programs and configurations, ensuring you always have access to the latest approved versions. Roll back to previous versions quickly if needed.

- Centralized Asset Management: Keep track of all your automation assets in one place, including hardware, software, documentation, and configuration files.

- Backup and Restore: Automate backups of your critical programs and configurations, ensuring you can quickly recover from failures and minimize downtime.

- Disaster Recovery: Develop and test disaster recovery plans which is very important to ensure business continuity in the event of a catastrophic failure.

- Compliance and Audit Trails: Maintain detailed audit trails of all changes made to your automation systems, simplifying compliance audits and demonstrating regulatory adherence.

- Reduced Downtime: Minimize downtime by providing quick access to backups, documentation, and other critical information, enabling faster troubleshooting and repairs.

- Enhanced Security: Control access to your automation assets with robust security features, preventing unauthorized modifications and protecting your intellectual property.

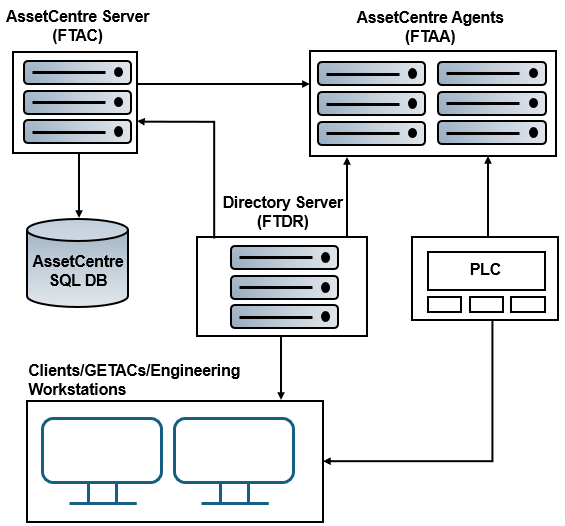

Components of AssetCentre – Architecture

Directory Server (FTDR): It is a central repository for security settings, user authentication, computer groups, and application configuration. It handles user authentication and authorization, ensuring that only authorized personnel can access and modify critical automation systems in a plant. The FactoryTalk Directory can be configured as a network directory, enabling centralized management across multiple computers and servers within a plant or facility. Once the installation is complete on AssetCentre server, Agents and Clients, all these machines should be connected to the FTDR server by specifying the FTDR hostname on each of these machines.

AssetCentre Server (FTAC): It is the core component of the architecture and management hub for automation asset information. It stores and organizes data related to PLCs, HMIs, drives, and other automation devices. It facilitates automated backups of device configurations, enabling quick recovery in case of failures.

AssetCentre Agents (FTAA): Depending on the complexity of the site, it can have one Agent Server or many. Agents handle the communication between the AssetCentre server and the automation devices, enabling the exchange of data and commands. Agents facilitate the automatic backup and comparison of device configurations, allowing for change detection and disaster recovery.

AssetCentre Database: The database is typically a Microsoft SQL Server database. It records the user actions, such as who made changes to configurations and when, and logs of device backups and restores. It also stores inventory and disaster recovery information. While installing and configuring AssetCentre Server, the AssetCentre Database server name must be entered with the service account to establish connection. It is recommended to use managed service accounts (MSA) from AssetCentre v11 and higher.

Clients: PCs, GETACs (Rugged laptops designed to withstand harsh environments and for rough use in plant shop floor), Engineering Workstations are the client machines. AssetCentre Client package must be installed on each of these machines. AssetCentre Client can be launched in both desktop and web mode. AssetCentre Web Client is a web application that provides access to the FactoryTalk AssetCentre system from a web browser. It allows to,

- View, filter, and sort logs

- Create, edit, delete, activate or deactivate, run, stop, filter, and sort schedules/searches

- View database information, set database limitations, analyze index fragmentation, and rebuild fragmented indexes

- Create a log cleanup schedule

- Create an archive cleanup schedule

- View the asset tree and archive workspace

- View, update, refresh, report lifecycle information

Activation Manager: Some organizations maintain a dedicated activation server in which all the FactoryTalk licenses would be hosted and activated. Activation Manager installs as a component in the AssetCentre package and must be installed on all servers and clients. Path must be updated with activation server hostname on all servers and clients. Some organizations also prefer FTDR server as activation server.

Conclusion

In today’s fast-paced industrial environment, effective asset management is crucial for success. FactoryTalk AssetCentre provides a powerful platform for streamlining industrial operations, reducing downtime, improving compliance, and enhancing security. By centralizing the automation assets and providing robust tools for managing them, AssetCentre empowers the manufacturers to optimize their production processes and achieve greater efficiency. Whether you’re looking to streamline maintenance, protect sensitive data, or simplify compliance reporting, FactoryTalk AssetCentre is an essential tool for modern industrial environments.