Industrial enterprises today stand at a pivotal crossroads. On one side, they face mounting regulatory and stakeholder pressure to reduce carbon emissions and meet Net Zero targets. On the other, they are under constant pressure to modernise legacy operations, improve efficiency, and increase resilience through digital transformation.

This dual mandate—sustainability and productivity—is no longer a choice. It is a necessity. Yet for many engineering professionals, the question remains: how?

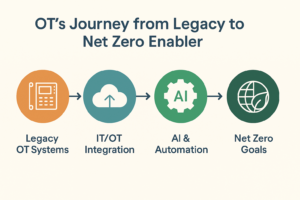

A growing number of organisations are finding the answer in a critical yet often under-recognised domain: Operational Technology (OT). Once confined to control rooms and plant floors, OT is now emerging as a strategic enabler. When enhanced with Artificial Intelligence (AI), it becomes a transformative force that not only delivers environmental benefits but also unlocks significant operational value.

In this article, we explore how AI-enabled OT is helping industrial sectors—from power generation to process manufacturing—navigate the path to Net Zero, while delivering tangible improvements in efficiency, reliability, and cost performance.

________________________________________

1. Repositioning OT: From Back-End Control to Frontline Strategy

Operational Technology (OT) refers to the hardware and software systems used to monitor, control, and automate industrial processes. This includes SCADA systems, Distributed Control Systems (DCS), programmable logic controllers (PLCs), and other embedded technologies that govern physical infrastructure.

Historically, OT systems were:

● Purpose-built and deterministic;

● Air-gapped from IT systems to ensure security.

● Designed to maintain stability, not adaptability.

Today, OT is undergoing a fundamental evolution. With advancements in IoT, connectivity, and AI, these systems are becoming more intelligent, more connected, and far more strategic in nature. As organisations adopt Industry 4.0 frameworks, modern OT platforms are now capable of supporting real-time data processing, predictive analytics, and autonomous optimisation.

________________________________________

2. Aligning OT with Net Zero Goals

Global Net Zero targets require enterprises to significantly reduce their Scope 1 and Scope 2 emissions—that is, direct emissions from owned assets and emissions from purchased energy. OT plays a vital role in this effort by enabling real-time visibility and control over high-emissions processes.

Key contributions of OT to sustainability include:

● Real-time emissions monitoring and compliance tracking;

● Energy optimisation through intelligent control strategies;

● Flexible load management and dynamic response to carbon intensity signals from the grid;

● Integration of renewable energy sources and support for hybrid systems.

Case in Point: Power Sector Application

A 500 MW thermal power plant in South Asia embarked on a transition from coal to natural gas. The switch posed numerous operational challenges, including process instability, efficiency drops, and increased maintenance overhead.

By deploying an AI-enhanced OT architecture—including control system retuning, predictive analytics, and emissions monitoring—the plant achieved:

● A 16% reduction in CO₂ emissions;

● A 3% increase in overall plant efficiency;

● A 10% decrease in unplanned outages;

● A return on investment in under two years.

This example illustrates how modern OT systems can be instrumental in decarbonising complex, asset-intensive operations.

________________________________________

3. Enhancing OT with AI: Moving from Reactive to Predictive

While traditional OT systems provide data and control, they are often limited to fixed logic and threshold-based alerts. When integrated with Artificial Intelligence, however, OT becomes exponentially more valuable.

AI models trained on historical OT data—such as pressure, temperature, vibration, and flow parameters—can identify patterns that precede faults or inefficiencies. This capability enables a shift from reactive responses to predictive and even prescriptive actions.

Common AI-OT Applications:

a. Predictive Maintenance

AI forecasts equipment failures and recommends maintenance windows that minimise disruption.

📈 Result: Up to 30% reduction in unplanned downtime and a 20% increase in asset lifespan.

b. Process Optimisation

Machine learning models continuously refine control setpoints based on input variability and environmental conditions.

📈 Result: 10–15% improvement in throughput, with lower energy usage per unit produced.

c. Real-Time Quality Control

AI algorithms detect anomalies and suggest real-time process corrections.

📈 Result: Reduced waste and rework, and improved batch yield consistency.

Industrial Example: Pharmaceutical Manufacturing

A European pharmaceutical plant used AI models trained on OT process data to predict yield variations. The system autonomously adjusted mixing and heating parameters, resulting in a 40% reduction in batch rejections.

________________________________________

4. OT as the Foundation of Industry 4.0

The benefits of OT extend beyond emissions reduction. When integrated into broader Industry 4.0 initiatives, OT becomes the foundation of smart, connected, and adaptive operations.

Enabling Technologies Driving this Transformation:

Technology Role in Net Zero & Industry 4.0

Edge AI Local analysis of OT data for real-time decision-making

Digital Twins Virtual replicas of processes for simulation and optimisation

IoT Sensors Granular visibility into operational performance

5G Connectivity High-speed data transmission across remote and critical assets

Cloud Integration Centralised insight and optimisation across global operations

When deployed holistically, these technologies deliver not only emissions reductions but also measurable productivity gains, asset longevity, and process resilience.

________________________________________

5. Bridging the IT/OT Divide: A Prerequisite for Scalable Impact

Despite the promise of AI-enabled OT, organisations must address long-standing barriers between operational and enterprise systems. Effective IT/OT convergence is essential to unlock the full potential of data-driven operations.

Common Challenges:

● Cybersecurity Risks

Legacy OT systems were not built for internet exposure.

✔ Solution: Adopt secure communication protocols (e.g., OPC UA, MQTT) and frameworks like ISA/IEC 62443.

● Skills Gaps

Many OT professionals lack AI or cloud expertise.

✔ Solution: Upskilling programmes, strategic partnerships, and cross-functional collaboration.

● Legacy Infrastructure Constraints

Older control systems may not support modern data interfaces.

✔ Solution: Use protocol converters, edge gateways, and stepwise modernisation strategies.

By progressively modernising legacy infrastructure and breaking down functional silos, industrial enterprises can achieve scalable and sustainable transformation.

________________________________________

6. The Future of Industrial Operations: Intelligent, Autonomous, Sustainable

Looking ahead, the integration of AI and OT will give rise to autonomous, self-optimising operations. These systems will be capable of:

● Embedding environmental performance directly into control logic;

● Adjusting to changing raw material or market conditions in real time;

● Providing auditable ESG metrics and sustainability insights directly through OT dashboards.

Future industrial systems will not only be optimised for performance—they will be optimised for impact, aligning operational decision-making with corporate climate and sustainability commitments.

________________________________________

Conclusion: OT Is No Longer a Cost Centre—It Is a Strategic Asset

As industry leaders re-evaluate their sustainability and digital transformation roadmaps, one thing becomes clear: Operational Technology is no longer just infrastructure. It is a strategic asset.

By modernising OT systems and integrating them with AI, organisations can accelerate their journey toward Net Zero while improving productivity, reducing costs, and strengthening resilience.

In the years ahead, the most successful enterprises will not treat Industry 4.0 and Net Zero as separate efforts. They will recognise them as two sides of the same coin—and position OT as the critical enabler at the centre.

Fig2: OT’s Journey for Net Zero Goals

________________________________________