A typical problem faced by the manufacturer involves accurate tracking of inventory to control costs. There is usually a mismatch in the inventory shown in systems and inventory at hand leading to inconsistency between the recorded and physical stocks. It causes issues related to either overstocking or stockout which ultimately hammer the financials of manufacturers.

Inventory Counting identifies discrepancies between the system’s records and the physical stock in the Warehouse, helping to reconcile differences caused by unrecorded movements or accidents over time. Its benefits include accurate inventory records, efficient inventory check, cost reduction due to prevention of overstocking and accurate stock data improves production scheduling. Its execution involves Journal creation either manually or automatically as per business rule i.e. Based on ABC Class etc., count inventory to enter data against open journal using MES terminal, Flag discrepancies for reconciliation and posting to ERP. Mainly Counter, Reconciler and Approver are the roles that get involved in this process. In special cases, two additional approvers are added to revalidate the final counting depending on inventory cost and properties.

It is recommended to perform inventory counting in MES as MES is executing the real time movement, assignment and consumption of inventory and integrated with other system to post aggregate data accurately. In MES, Inventory counting happens in following four different ways.

• Full Inventory Count

The Full Inventory Count encompasses all items in the Warehouse, counting everything without criteria related to location, status, or classification. The process outlined in this strategy involves checking existing inventory, preparing the count procedure, creating count disposition and lines, executing the count, checking progress, performing sign-off, beginning reconciliation, and posting results to ERP.

• Inventory Count in Manually Selected Warehouse Locations

The main distinction is that the Full Inventory Count includes all Warehouse Locations in a specific Warehouse, whereas this strategy focuses only on the Warehouse Locations that are manually selected during the Count Disposition setup.

• Inventory Count Based on the ABC Class.

An ABC Class Inventory Count organizes how frequently products are counted based on their classification, with high-value or regulated items often utilizing this method to ensure accurate inventory management. An ABC Class is commonly utilized for tracking high-value items, hazardous substances, or products subject to legal agreements. ABC analysis allocates a specific value to each item in inventory management. This indicates that products with greater value are counted more often compared to those with lesser value.

• Group Closed Counting.

To determine whether there are any inaccuracies in counting, count a small group of things several times over a brief period, according to this kind of counting approach. This will also highlight any problems with the counting method that could be contributing to the mistakes. Until all counting problems are fixed, this process is repeated.

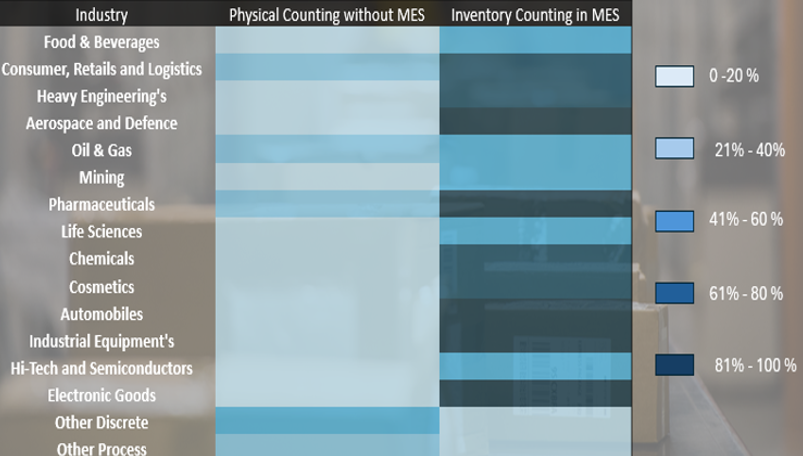

The industry wise usage of inventory counting using MES is as below.

The Pros and Cons of Inventory counting is important to know.

• Pros: Uncovering Hidden Inventory, Continuous Monitoring, Prioritizing Fast-Moving Items, Flexibility in Scheduling

• Cons: Dependence on Warehouse Management Systems, Potential for Missing Items, The Fine-Tooth Comb Approach, Time Consumption

The basic difference between Manual Counting (Full Inventory Counting) without MES and Inventory Counting using MES is that MES automatically generate counting journals with alert and force counter to execute the inventory counting as respective stock has been reserved under “Counting” reason code.

The future of Inventory counting is inclined towards Image processing and Augmented Reality advancement, subject to adaptability by manufacturer. It is believed that in near future, technology is expected to move in a direction to avoid manual physical counting. Experts believe that Inventory counting will be a matter of long scan of locations. It will save huge effort in term of time and mental stress.

Swarm Analysis can play a major role in inventory counting by grouping inventory in defined pattern for fast counting. It will be key for future technology to adapt it.

It’s a great read.