Global disruptions such as Brexit, Suez Canal blockage, weather events or COVID-19 pandemic induced shortages, is pushing corporates to accelerate the transformation of storage management and warehousing sector. The concept of stockpiling goods as a business strategy, to counter variation in demand and supply is now core to daily operations. However, it requires businesses to manage storage space in an optimal manner.

COVID-19 has spurred e-Commerce growth. The total online spending by consumers in May 2020 was up 77% from the previous year. This has led companies to pivot to online business models with faster fulfilment cycles. In effect, the increased dependence on eCommerce along with the shortage of labor is straining the warehouse sector. Looking ahead, companies will face increasing pressure to meet consumer expectations of delivery-on-demand while balancing the higher costs of providing such a service.

Here are some mitigation strategies:

Strategize on warehouse space: The surge in e-Commerce sales is leading companies to seek more warehouse space to store and ship products. The availability of such space is becoming scarce. Moreover, warehouses need to operate as full-service fulfilment centers. Industrial real estate firm Prologis reported that warehouse vacancy rates in US are at 4.7% nationally, which is an all-time low. Rather than trying to obtain their own space, many organizations have started outsourcing this to a third-party logistics provider that can provide space, labor, and logistics support for order fulfilment. Additionally, these services can be tailored to specific industry needs such as cold storage units for short shelf life or pharmaceutical products.

Organizations are also considering mobile warehouses as an effective solution to the issue of last-mile logistics. These are essentially trucks or trailers that carry the inventory based on the estimated demand requirements of a particular region or geography. Other organizations are also looking into temporary storage facilities using the existing space from small-ticket retail stores to cover short-term needs and complement home delivery models within cities.

Automate to manage labor better: The availability of labor is potentially the most serious issue that has arisen since the COVID crisis. Warehouses must consider the feasibility of automation to reduce dependency on repetitive labor-intensive processes.

Many organizations are investing in AI, robotics, conveyors, cloud-based data analytics, assisted guided vehicles, forklift automation, smart sorting, and efficient WMS systems. But automation can only replace repetitive operational processes and there will remain certain dependencies on human labor. Companies should factor this in when they look at the labor pool availability based on geography and, hence, re-strategize their warehouse locations in a cost-efficient manner.

Touchless warehousing for health and safety: Apart from automating for efficiency, organizations should also consider automation for operational safety. Labor health and safety in a post-pandemic world is key to an effective warehouse strategy. This includes making warehouse processes more touchless and automated. They ought to establish robust safety protocols that keep the workforce safe and healthy, thereby averting any labor disruptions that would affect warehouses operations.

Stay ahead of inventory stockouts: Supply chain disruptions tend to trigger panic buying among consumers resulting in stockpiling and, eventually, exacerbating stockouts. Companies must evaluate safety stock limits with a good balance of inventory holding cost, stockout costs and customer service.

Factors disrupting the supply chain will continue to happen. Organizations need to build financial models that gauge the impact of various disruption scenarios and decide how much to invest in the mitigation of specific gaps in their warehouse strategy.

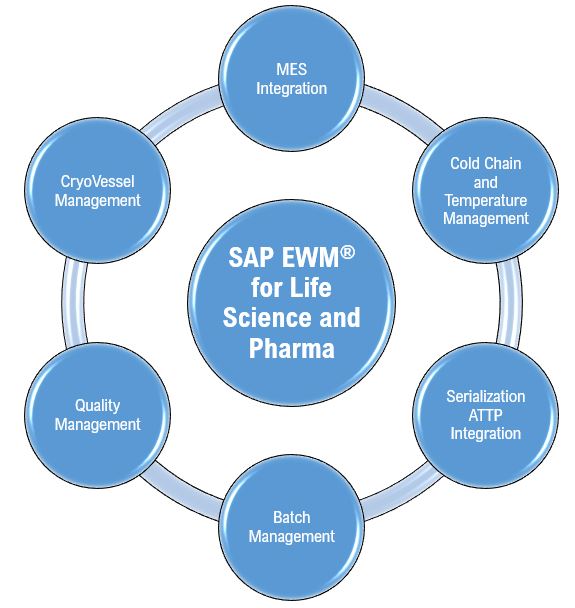

SAP product offerings such as Analytics on Cloud, SAP Integrated Business Planning (IBP), SAP Extended Warehouse Management Material Flow System (EWM MFS), SAP Environment, Health, and Safety (EHS), and S/4 HANA Cloud for Supply Chain are proven to effectively bridge some of these gaps.