Introduction

In the first part of our article, we explained the focus area for organizations to master asset and engineering information management capabilities. While the “EIM Pentagon” framework introduced in the previous article was focused on “Break down the siloes” area, it is a guidance on organization overall journey. This article focuses on how you can measure the progress made and what can be the actions that organizations need to follow through for sustaining the benefits of breaking the siloes.

The 5 focus areas of breaking down siloes are Process, Standards, Governance, Technology Adoption, and Data. The progress that is made in each of the 5 area towards this aspirational state mentioned in the part 1 article can be evaluated with 4 levels of maturity.

- Inadequate: Organizations are not aware of the importance of any of the aspects.

- Aware Level: There is some level of awareness but there is limited infrastructure.

- Reactive Level: Energy and efforts are being spent on consolidating and standardizing.

- Proactive Level: Actively managing with bots, digital tools and automated workflows.

Integrate information with processes

There needs to concerted efforts to follow through the “break down the silos” initiatives. These can start in parallel to break down the silos and after organization reaches at least reactive level of maturity in 3 of the 5 focus areas. Organizations must strive towards building integrations between EIM, enterprise applications and plant applications. The full potential of an Asset Information Management system will remain untapped unless there is interoperability between EIM Application and Enterprise applications, as explained in one of our articles.

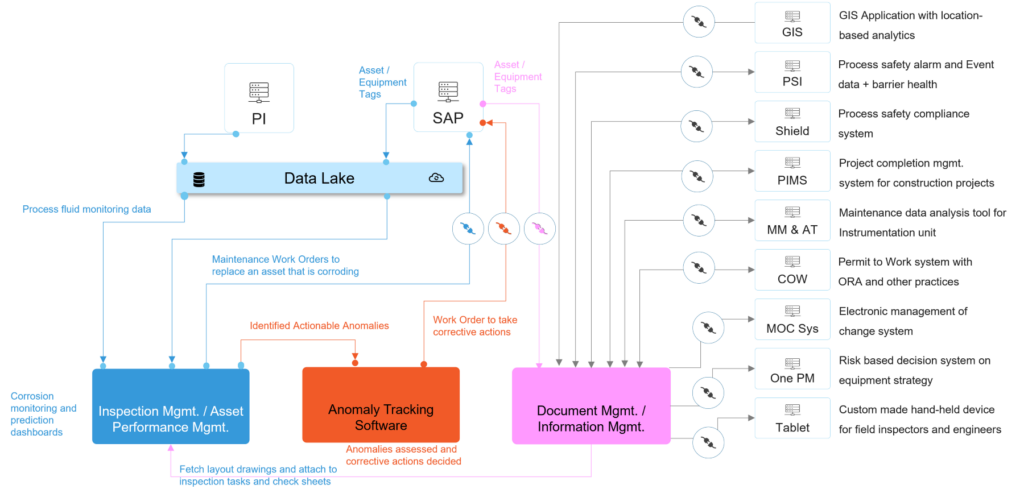

In an ideal scenario, a user will not have to use multiple systems for overlapping functions. A user will use a single system to perform work and this system will be able to orchestrate workflows in a different system for another user to pick up. An inspection engineer would like to use the Integrity Management tool to focus only on analyzing various inspection readings and identify anomalies that needs to be fixed and not be worried about the right ways of creating a maintenance work order in the Maintenance Management software such as SAP (CMMS). It will help him plan a risk-based inspection (RBI) of the asset if he is able to get a virtual replica of the asset or access the latest layout isometrics for the asset on a click of button, without separately logging into two separate software (digital twin software or EIM software) and navigate them. For a typical energy company, a fully integrated ecosystem would look something like this.

Navigating the selection and prioritization of integration use cases becomes challenging when balancing the trade-offs between potential gains and resource limitations. Several applications today are provided as SaaS (software as-a-service) by software vendors, making implementation of custom changes required for integration a challenge. This is because Product Managers of these software vendors will have a pre-decided release management schedule based on multiple customer’s request. Once the problem is determined and integrating two systems is decided as the best solution, evaluating and prioritizing the use cases will be a challenge. This can be made easy if “evaluation criteria of expertise” devised by Schwartz, List and Mueller is used[1]. The evaluation is done based on 3 broad parameters listed below:

- Potential – evaluate business value, benefits, strategic fit etc.

- Technical – data access. Data security, data quality, SME availability etc.

- Economic – Costs, timelines, dependencies, etc.

All use cases need to be scored on a scale of 1 to 5 based on this evaluation criteria and rank them based on the total score. A priority can be determined based on this ranking and the top ranking one will have the top priority.

Conclusion

The concluding objective of maturing the EIM systems and having them digitally integrated is to build a virtual replica of all your assets. Deploying the right digital twin solution and selecting the correct use cases for your organizations are as critical as the approach and pre-requisites required for deploying digital twin solutions. Our colleagues have explained how to get the digital twin implementation right, through their POV. These activities need to happen in conjunction with Step 1 and Step 2 mentioned in this POV.

As the shift towards sustainable energy intensifies, the need for efficient asset management that will prolong the asset life and optimize resources will become more critical. A robust management of Asset / Engineering information will be the key differentiator among energy players. This requires a concerted effort to break down information silos, integrate information with processes, and develop an analytics and presentation layer for virtualization.

Implementing a robust framework such as “EIM pentagon” for all its efforts will help organizations to seize better opportunities. This will allow the organizations to leverage the power of technology to ensure an accurate virtual representation is implemented, ultimately enhancing asset / engineering information management efforts.

References

University of Hawaii: A Framework for the Systematic Evaluation of Data and Analytics Use Cases at an Early Stage by Dustin Schwarz, Michael List, Rolan M Mueller. Proceedings of the 56th Hawaii International Conference on System Sciences, 2023

Infosys Consulting Insights: Failing in the virtual world is not expensive. Get your Digital Twin implementation right. By Balasubramanian Chandrasekaran, Dhiraj Rane, Gautam Saha, Prem Paramasivam, 2022.

LinkedIn Article by Pranav Gupta: Building Bridges: How Engineering Information Management Connects the Dots in Oil and Gas Industry.

Unlocking the Full Potential of Asset Visualization in the Oil and Gas Industry: By James Fisher and Sons plc.

GE Digital Blog on Future of Oil & Gas Industry: Digital Transformation in Oil and Gas: Balancing Uncertainty and Net Zero goals while seeking profitability by Francis Kusznir of GE Vernova.

Gartner Study: A Gartner study has revealed that 47% of employees struggle to find the right information to perform their work.