The Transformation is Already Here

By 2030, intelligent agents capable of autonomous decision-making will be embedded in nearly half of all supply chain management platforms. This isn’t speculation—53% of organizations are already enabling autonomous automation through AI agents, and companies with higher AI investment achieve 61% greater revenue growth than their peers.

The shift from automation to autonomy represents a fundamental change: AI agents don’t just follow rules, they sense, reason, decide, and continuously learn from outcomes.

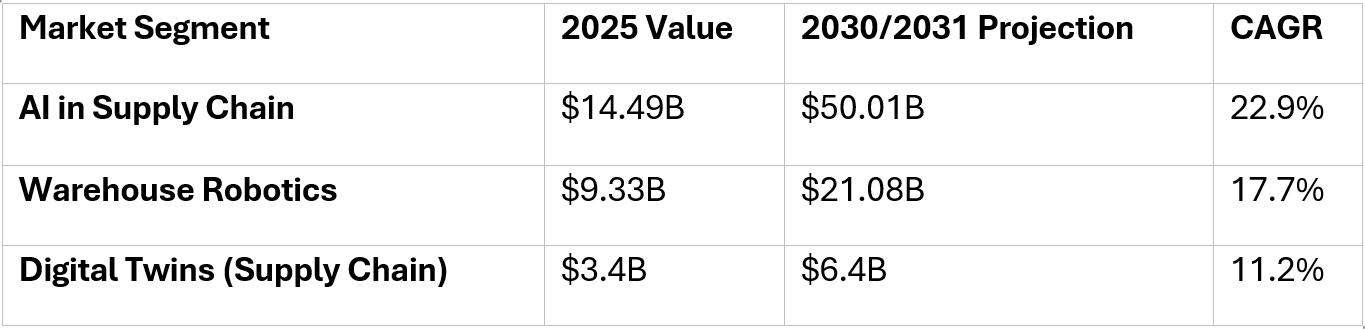

Market Momentum: The Numbers Tell the Story

The warehouse robotics market alone will more than double in five years, driven by explosive e-commerce growth and labor challenges.

Three Pillars Driving Autonomous Operations

1. Intelligent Robotics: Beyond Simple Automation

Industry Leaders Scaling Now

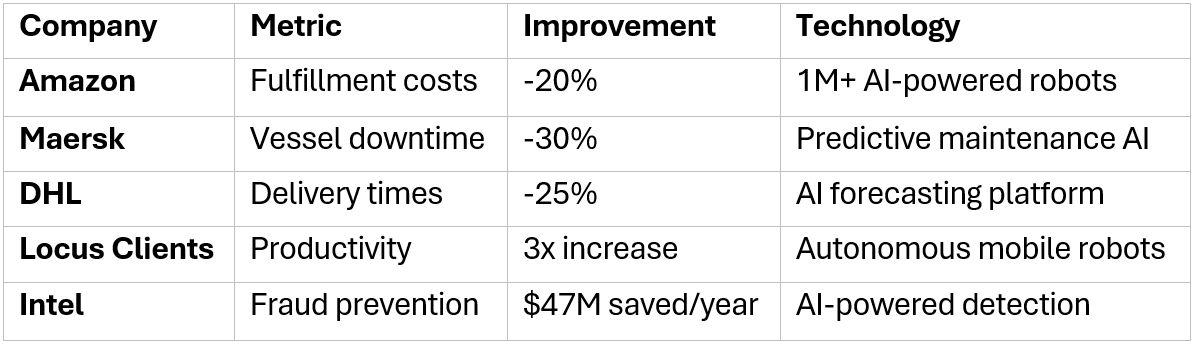

Amazon’s Robot Army Amazon now operates over 1 million robots across 300+ facilities, reduced fulfillment costs by 20% while increasing order processing capacity by 40% per hour. Their AI-powered systems achieve 99.8% picking accuracy.

Symbotic’s Walmart Deal Symbotic acquired Walmart’s robotics division for $200 million and received a $520 million investment, demonstrating retail’s commitment to full-stack warehouse automation.

Locus Robotics’ Productivity Leap Locus clients report productivity jumping from 30-40 units/hour to 120-150 units/hour—a 3x improvement. DHL deployed over 3,000 Locus AMRs globally, dramatically improving accuracy and throughput.

Emerging Innovators

- Covariant: AI software enabling robots to perform complex manipulation tasks with their “Covariant Brain”

- Control One (India): Converts conventional warehouse equipment into autonomous machines using voice commands and physical AI

- Geek+: Largest global provider of autonomous mobile robots, serving Nike and Walmart

2. Digital Twins: Testing Reality Without Risk

Digital twins mirror real-world supply chains in virtual environments, allowing organizations to model and test disruption scenarios before they happen.

Real-World Applications

Amazon’s LIDAR-Powered Twins Amazon uses LIDAR scanning to create 3D digital twins of fulfillment centers, decreasing build time by up to 80%. Engineers scan facilities to produce dense point clouds enriched with metadata like rack IDs and equipment specs.

Walmart’s Demand Intelligence Walmart’s digital twins analyze real-time sales data, weather conditions, historical patterns, and macroeconomic indicators to predict demand and dynamically adjust procurement.

Ford’s Complexity Management Ford maintains 50+ plants using 35 billion parts to produce 6 million vehicles annually. Digital twins help simulate disruptions across this complexity before they materialize.

Key Capabilities

- Predictive Analytics: Anticipate disruptions before they cascade

- Risk-Free Testing: Model port closures and watch revenue-at-risk update in real-time

- Accelerated Decision-Making: When scenarios become real, mitigation playbooks are pre-packaged

3. End-to-End Orchestration: The Autonomous Nervous System

Demand Forecasting Excellence

Amazon Pharmacy’s AI Platform Amazon Pharmacy’s AWS supply chain solution achieved forecasting accuracy that is 50% higher than industry benchmarks using ML analysis of historical sales and current trends.

Logistics Optimization at Scale

Maersk’s Maritime Intelligence Maersk deploys advanced AI systems that ingest over 2 billion operational signals each day from a fleet of 700+ vessels. By continuously analyzing engine performance, sensor data, and operating conditions, these platforms can anticipate equipment failures up to three weeks in advance with 85% predictive accuracy.

Impact: This capability has driven a 30% reduction in unplanned vessel downtime, generating over $300 million in annual savings, alongside a 15% cut in fuel consumption through smarter operational optimization.

DHL has embedded AI-powered forecasting across its global logistics network, reducing average delivery times by 25% across operations spanning 220 countries. At the same time, forecasting precision has improved to 95% accuracy, enabling tighter planning and execution.

Its Smart Trucks leverage real-time traffic, weather, and demand signals to dynamically reroute shipments, eliminating inefficiencies and saving over 10 million delivery miles each year.

Risk Management in Action

Toyota uses AI to continuously oversee a supplier ecosystem of more than 175,000 tier-1 to tier-3 partners, scanning for early indicators of supply risk. The system identifies potential disruptions with 91% accuracy, allowing teams to respond before issues escalate.

During recent flooding events, Toyota’s platform flagged critical component risks 11 days ahead of on-the-ground impact, enabling rapid mitigation and production continuity.

Johnson & Johnson operates an AI-based risk intelligence platform that tracks 27,000+ suppliers across 100+ countries. The system processes over 10,000 risk indicators daily, spanning geopolitical, environmental, operational, and financial signals.

Outcome: The platform provides early alerts for 85% of major supply disruptions, delivering an average seven-day lead time—crucial for proactive sourcing and resilience planning.

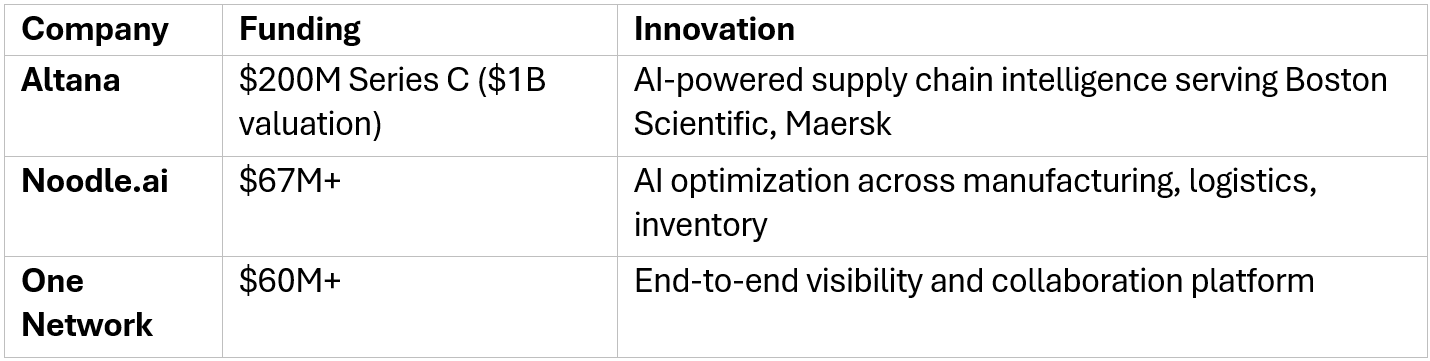

The Startup Revolution: Innovation Accelerators

Major Funding & Breakthroughs

Supply chain AI startups have collectively raised over $560 million, with notable rounds including:

Y Combinator’s Supply Chain Cohort

Y Combinator has funded 72 supply chain startups, including:

Autonomous Execution:

Spherecast: Autonomously executes inventory decisions by communicating with suppliers

Panora: Automates PO entry, reclaiming ~80% of order-entry time

Supadock: AI agents using cameras, voice, and documents to automate warehouse workflows

Logistics Intelligence:

Nowports: First digital freight forwarder for Latin America, reducing mistakes to 0% and delays by 40%

Trackstar: “Plaid for supply chain logistics” providing universal API for hundreds of WMS systems

Cartage (YC): Building transparent, tech-driven freight coordination

Measurable Business Impact

Performance Improvements Across Leaders

Industry-Wide Gains

Early adopters of AI in supply chains achieve a 15% reduction in logistics costs, a 35% improvement in inventory efficiency, and a 65% uplift in service levels. Companies implementing autonomous solutions achieve up to 30% reduction in inventory costs while improving service levels.

Implementation Blueprint

Phase 1: Foundation (Months 1-6)

Data Infrastructure: Establish governance and integrate disparate systems (WMS, TMS, ERP)

Strategic Pilot: Choose high-quality data use cases with clear ROI (single warehouse, specific route)

Reality Check: On average, logistics organizations leverage just 23% of their available data to support AI use cases.

Phase 2: Scale (Months 6-18)

Modular Deployment: Plug AI agents into high-impact areas without full system replacement

Multi-Agent Collaboration: One agent checks order status, another inventory, another expedite costs

Example: Maersk aims to handle up to 80% of logistics tasks with AI within five to seven years, seeing efficiency gains of 30-50% on existing processes

Phase 3: Ecosystem (Months 18-36)

Cross-Function Integration: Connect procurement, logistics, warehouse operations

Partner Extension: Extend digital twin visibility to suppliers and distributors

Advanced Capabilities: Maersk uses AI-driven chatbots to negotiate multi-million dollar deals with suppliers

Critical Success Factors & Challenges

What Makes or Breaks Implementation

Data Readiness Is the Foundation

In most AI initiatives, 60–70% of total project spend goes toward data cleansing, labeling, and integration, not model development. Organizations that have established formal data governance frameworks are 3.2× more likely to achieve successful AI outcomes, underscoring that data quality—not algorithms—is the primary differentiator.

The Integration Challenge

Only 34% of enterprises report smooth, end-to-end data flow between physical assets and AI-driven systems. Legacy infrastructure and siloed platforms remain key barriers.

What works: API-first architectures, modular system design, and cloud-native, unified data platforms significantly reduce integration friction.

The Economic Reality

Deploying enterprise-scale AI platforms for logistics typically requires an upfront investment of $500K to $2.5M, with ongoing maintenance costs of 15–20% annually. Despite these costs, the economics are compelling—McKinsey finds a median return of 3.5× on investment within three years for successful implementations.

People, Skills & Cultural Shift

While 70% of CEOs acknowledge AI as mission-critical for inventory control, logistics optimization, and supplier risk management, execution remains difficult. Upskilling teams, redefining workflows, and embedding AI into daily operations demand sustained change management and cultural transformation, not just technology deployment.

The 2030 Vision: Autonomous Operations in Action

A Cold Front Approaches the Southeast US

An AI agent detects unusual demand patterns for winter coats. Within milliseconds, it autonomously:

- Analyzes historical sales correlations with temperature drops

- Adjusts inventory across 12 regional warehouses

- Reroutes 47 shipments to maximize coverage

- Negotiates expedited shipping with 3 carriers

- Updates production schedules with 5 Asian suppliers

- Communicates personalized ETAs to 10,000+ customers

- Optimizes for cost, speed, experience, and carbon footprint—simultaneously

- The regional manager reviews the dashboard and approves with one click. Execution completes in seconds.

Characteristics of 2030 Supply Chains:

- Self-healing (80%+ disruptions resolved autonomously)

- Predictive (digital twins identify issues before they happen)

- Collaborative (humans focus on strategy, AI handles execution)

- Sustainable (built-in environmental optimization)

- Transparent (real-time visibility across partners)

The Imperative: Act Now or Fall Behind

The Window is Narrowing:

First Movers: Building data advantages, attracting top talent, refining AI muscle

Fast Followers: Can catch up with decisive action and strategic partnerships

Late Adopters: Will face insurmountable capability gaps

Market Reality: By 2030, intelligent agents capable of autonomous decision execution will be embedded in roughly half of all supply chain management platforms. With 40% of companies already using agentic AI and another third experimenting, the competitive landscape is rapidly shifting.

Your Action Plan:

- Invest strategically in AI platforms, IoT sensors, digital twins

- Prioritize data excellence and system integration

- Embrace cultural change around human-AI collaboration

- Implement in phases with clear ROI milestones

- Build ecosystem partnerships with suppliers and tech providers

Key Takeaways

✓ 50% of supply chain solutions will use autonomous AI agents by 2030

✓ 61% revenue growth premium for companies with higher AI investment

✓ Amazon deployed 1M+ robots; Maersk saves $300M annually; DHL cut delivery times 25%

✓ $560M+ raised by supply chain AI startups; 72+ Y Combinator-backed companies

✓ 3.5x median ROI over three years for AI initiatives (McKinsey)

✓ Early adopters improve logistics costs 15%, inventory levels 35%, service levels 65%

✓ Data quality and governance are the #1 success factors

✓ The time to act is now—competitive advantages compound rapidly

The autonomous supply chain revolution is happening. Leaders like Amazon, Maersk, DHL, Walmart, and Toyota are demonstrating what’s possible. Startups like Altana, Covariant, and Symbotic are pushing boundaries. The only question: Will you lead, follow fast, or get left behind?